What is Logistics?: A Guide to Its Core Components & Why It’s Crucial?

Table of Contents

What is logistics ?

Logistics meaning- underpins the success of every product delivered. More than just “shipping stuff,” it’s a sophisticated discipline pivotal to supply chain management. Logistics ensures efficient, cost-effective movement of raw materials to finished goods from origin to customer. This focus on seamless flow is crucial for logistics optimization and staying competitive in 2025.

At its core, logistics involves the detailed planning, implementation, and control of the efficient forward and reverse flow and storage of goods, services, and related information from origin to consumption. Its ultimate goal is to precisely meet customer requirements. Often called the “glue” of the supply chain, robust logistics prevents delays and inefficiencies. While a critical component of supply chain management, logistics specifically concentrates on the movement and storage of resources, making understanding its definition foundational for any business.

A Simple Way to Define Logistics Management:

The primary objective of logistics management is to ensure you have the:

- Right product

- At the right quantity

- At the right time

- In the right condition

- Delivered to the right place

- For the right customer

- At the right cost

This framework, often known as the “Seven Rs”, the essence of effective logistics.

You May Also Like to Read: Automation In Supply Chain Management, Logistics & Road Transport

Why Is Logistics So Important in Today's Business?

In an era of hyper-connectivity and global trade, efficient logistics isn’t just a bonus; it’s a fundamental necessity for business survival and growth. The importance of logistics cannot be overstated.

Cost Reduction & Profitability

Streamlined logistics processes minimize operational costs, reduce waste, optimize inventory levels, and prevent costly delays, directly impacting your company’s bottom line.

Enhanced Customer Satisfaction

On-time, accurate, and undamaged deliveries lead to happier customers. In the age of omnichannel commerce and same-day delivery expectations, reliable logistics is paramount for meeting demand and fostering loyalty. This highlights the connection between logistics and customer satisfaction.

Competitive Advantage

Companies with superior logistics can offer faster delivery times, lower prices, and better service, gaining a significant edge over competitors.

Increased Efficiency

Effective logistics management ensures smooth material flow, prevents bottlenecks, and maximizes resource utilization across the entire supply chain. This leads to improved supply chain efficiency.

Risk Mitigation

Robust logistics planning includes strategies for managing disruptions, such as unforeseen events or supply chain interruptions, ensuring business continuity.

Global Reach

For businesses operating internationally, expert logistics is essential for navigating complex customs regulations, diverse transportation networks, and varying delivery standards.

The cost of poor logistics can be steep. Industry research in 2020 found that over 60% of US and European companies lost up to 20% in revenue due to logistical disruptions. And in e-commerce logistics, 37% of online consumers will shop with another brand if they encounter an out-of-stock message. These figures underscore why taking your logistics seriously is not an option, but a necessity.

You May Also Like to Read: Ways To Improve Your Customer Services In Logistics

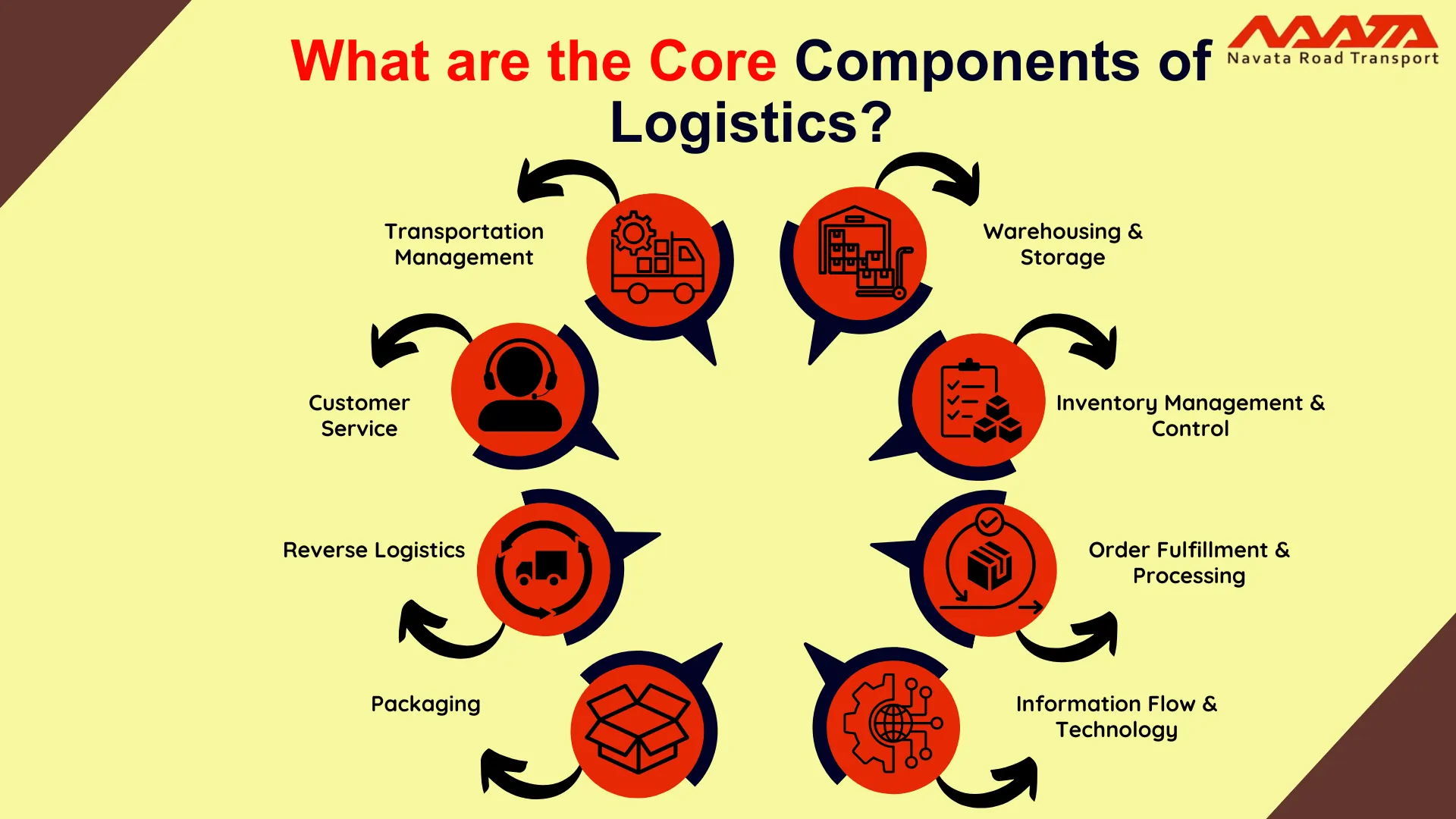

What are the Core Components of Logistics?

Logistics isn’t a single activity but a unified system comprised of several interconnected logistics functions. Managing these logistics components holistically is crucial for optimal performance.

1. Transportation Management

This is often the most visible part of logistics. Transportation management system focuses on the planning, optimization, and execution of moving goods from one location to another. It involves:

- Mode Selection: Deciding on the most appropriate transportation method (road, rail, air, ocean, pipeline) based on cost, speed, distance, and cargo type.

- Route Optimization: Finding the most efficient paths to reduce travel time, fuel consumption, and costs.

- Carrier Management: Selecting and managing relationships with various carriers, considering their price, availability, and capacity.

- Fleet Management: Overseeing a company’s own vehicles, including maintenance, scheduling, and tracking.

- Freight Auditing & Payment: Ensuring accurate billing and timely payments for transportation services.

Modern Transportation Management Systems (TMS) software is essential here, providing real-time tracking, analytics, and automation to streamline complex transportation logistics networks.

2. Warehousing & Storage

Warehousing involves the strategic storage and management of goods before they are transported to their next destination or the final customer. Key warehouse management functions include:

- Receiving & Putaway: Efficiently unloading incoming goods and placing them in designated storage locations.

- Inventory Storage: Protecting and organizing goods until needed.

- Order Picking: Retrieving specific items from storage to fulfill customer orders.

- Packing & Shipping: Preparing orders for dispatch, including appropriate packaging and labeling.

- Cross-docking: Moving goods directly from an inbound truck to an outbound truck, minimizing storage time.

- Material Handling: The movement, protection, storage, and control of materials and products throughout the warehousing process, often involving specialized equipment.

Warehouse Management Systems (WMS) are vital for optimizing warehouse layout, tracking inventory movement, managing labor, and improving overall operational efficiency.

3. Inventory Management & Control

This component deals with managing stock levels to meet demand without incurring excessive holding costs or experiencing stockouts. Effective inventory management involves:

- Demand Forecasting: Predicting future customer demand to ensure adequate supply.

- Stock Level Optimization: Determining optimal reorder points and quantities.

- Real-time Tracking: Monitoring inventory movement and levels continuously using technologies like barcoding, RFID, and advanced software. This is a core part of inventory control.

- Inventory Auditing: Regularly verifying physical inventory against records.

- Just-in-Time (JIT) Inventory: A strategy to minimize inventory and associated costs by receiving goods only as they are needed.

Poor inventory management can lead to lost sales due to stockouts or high carrying costs from overstocking. Automation, often powered by AI in logistics, is transforming inventory management by providing more accurate forecasts and automated reorder triggers.

4. Order Fulfillment & Processing

Order fulfillment encompasses the entire process from receiving a customer order to its delivery. This critical component directly impacts customer satisfaction and typically includes:

- Order Entry & Verification: Receiving and validating customer orders.

- Order Picking & Packing: Retrieving items and preparing them for shipment.

- Shipping & Dispatch: Handing over packages to carriers for delivery.

- Customer Communication: Providing order updates, tracking information, and post-delivery support.

Key metrics like Picking Accuracy Rate (percentage of correct orders) and Order Accuracy Rate (first-time delivery success) are crucial for measuring performance in this area.

5. Information Flow & Technology

The seamless flow of information in logistics is the nervous system of modern logistics. Technology connects all components, enabling visibility, control, and real-time decision-making. Key technologies include:

- Logistics Management Systems (LMS): Integrated platforms that manage various logistics functions.

- Warehouse Management Systems (WMS): Software for optimizing warehouse operations.

- Transportation Management Systems (TMS): Software for planning and executing transport.

- Enterprise Resource Planning (ERP) Software: Integrated systems that often include logistics modules.

- IoT (Internet of Things): Sensors for real-time tracking of goods and assets.

- Blockchain: For enhanced transparency and security in supply chain transactions.

- Artificial Intelligence (AI) & Machine Learning (ML): For predictive analytics, demand forecasting, route optimization, and automating processes.

The complexity of logistics processes in the modern era has necessitated these specialized software solutions and the rise of logistics-focused firms.

6. Packaging

Often overlooked, product packaging plays a vital role in logistics. It’s not just about aesthetics; it’s about:

- Product Protection: Safeguarding goods from damage during handling, storage, and transit.

- Space Optimization: Designing packaging that maximizes space utilization in warehouses and transport vehicles, reducing costs.

- Compliance: Meeting industry and regulatory standards for safety and handling.

- Sustainability: Choosing eco-friendly materials and designs.

Efficient packaging can significantly impact both transportation costs and customer satisfaction (e.g., preventing breakages).

7. Reverse Logistics

While most logistics focuses on the forward flow of goods, reverse logistics manages the return of products from the customer back to the point of origin. This includes:

- Returns Management: Processing customer returns for refunds or exchanges.

- Repairs & Refurbishment: Handling products sent back for servicing.

- Recycling & Disposal: Managing end-of-life products responsibly.

The reverse logistics process is particularly pertinent to e-commerce logistics, where return rates can be high. Efficient reverse logistics can turn a cost center into an opportunity for customer retention and even value recovery.

8. Customer Service

While not a direct physical flow component, robust customer service is integral to logistics. It involves:

- Providing timely and accurate information about orders and deliveries.

- Addressing inquiries and resolving issues efficiently.

- Managing documentation.

- Ensuring a positive experience throughout the delivery process.

Ultimately, good logistics aims to deliver a superior customer experience, making customer service in logistics a key part of the feedback loop.

What is the Difference B/W Logistics & Supply Chain Management?

It’s common for these terms to be used interchangeably, but it’s important to understand their difference between logistics and supply chain management:

Logistics Management: This is an important component within SCM. It focuses specifically on the efficient and effective movement and storage of goods, materials, and information within that broader supply chain. It’s the part of the supply chain that your business often has direct control over, dealing with the practical execution of transport, warehousing, and inventory.

Supply Chain Management (SCM): This is the broader, overarching concept. It encompasses the entire network of activities involved in the sourcing, procurement, conversion of raw materials into finished goods, and the distribution of those finished goods to the end consumer. SCM involves strategic planning, collaboration with suppliers and distributors, and managing relationships across the entire ecosystem. It often includes elements your business has little direct control over.

Read More About What is Transportation and Logistics?

What are the Different Types of Logistics?

Beyond the commonly discussed inbound logistics (materials coming in) and outbound logistics (products going out), several specialized types of logistics exist:

Procurement Logistics: Focuses on sourcing and acquiring raw materials, components, and supplies from vendors, ensuring timely delivery for production.

Production/Manufacturing Logistics: Manages the in-house movement, storage, and handling of materials and semi-finished goods within a manufacturing plant to optimize production flow.

Distribution Logistics: Concerned with the timely delivery of finished products to consumers, either directly from the manufacturer or indirectly via retailers and wholesalers. This also includes optimizing packaging and shipping methods for the final leg.

Disposal Logistics: Similar to reverse logistics but broader, it encompasses processes for disposing of waste and residual materials throughout the supply chain, including recycling and recovery efforts to maximize efficiency and minimize environmental impact.

How to Optimize Your Logistics Strategy?

In an increasingly competitive and complex market, optimizing your logistics strategy is no longer a luxury but a strategic imperative. Here’s how to approach it for effective logistics optimization:

Define Your Goals

Before making changes, clearly establish what you want to achieve. Common goals include:

- Reducing logistics costs

- Improving customer delivery times

- Reducing overstocking and waste

- Increasing revenue

- Improving overall supply chain visibility

Embrace Artificial Intelligence (AI) and Automation

AI is poised to revolutionize logistics. According to a McKinsey study, AI in logistics has helped businesses improve logistics costs by 15%, inventory levels by 35%, and service levels by 65%. This highlights the role of AI in logistics optimization 2025.

- Inventory Management: AI-powered software can provide highly accurate demand forecasts by analyzing vast datasets, automate procurement triggers when stock is low, and optimize warehouse slotting.

- Warehousing: Indoor mobile robots are a key innovation identified by DHL’s Logistics Trend Radar. These robots use real-time path planning to find the most efficient routes for order fulfillment, significantly reducing costs and labor. Reviewing your warehouse layout and placing best-selling products closer to shipping stations also makes a big difference. This shows how to improve warehouse logistics.

- Transportation: Intelligent route planning software (e.g., Stream, OptimoRoute) utilizes AI to plan, optimize, and schedule the most efficient delivery and collection routes, considering real-time traffic, vehicle capabilities, and multiple locations. This translates to significant time and cost reduction strategies in logistics.

- Packaging: Optimize packaging to be less excessive and more efficient. Less material means less cost and space used in warehousing and transport, and contributes to sustainability goals.

- Delivery: Offer customers multiple delivery options (e.g., specific time slots, leave with neighbor, parcel locker) to improve your first-time delivery success rate, reducing failed attempts and associated costs.

Consider Outsourcing (3PLs & 4PLs)

- Third-Party Logistics (3PL) providers manage specific aspects of your logistics, such as warehousing, transportation, or customs management, while you retain overall oversight.

- Fourth-Party Logistics (4PL) providers take on a broader, more strategic role, managing and optimizing your entire supply chain, including relationships with other 3PLs and your own internal logistics operations. Outsourcing can relieve businesses of time-consuming and costly processes, especially for SMBs. This addresses how do 3PL and 4PL providers work.

Conclusion

Logistics is far more than just moving goods; it’s a strategic function that can make or break a business in 2025. By optimizing your logistics, you improve efficiency across all points of the supply chain, adding immense value to the customer experience while simultaneously cutting costs and boosting your bottom line.

Understanding how to get the right resource to the right place at the right time is the differentiator in today’s competitive landscape. Invest in robust logistics, embrace technology like AI, and watch your business thrive.

Thank You For Reading: What is Logistics?: A Guide to Its Core Components & Why It's Crucial?

Powered By 360Presence

what is logistics what is logistics