Outbound Logistics – Understanding Definition, Process and Activities

Table of Contents

What is Outbound Logistics ?

Outbound logistics involves transporting, storing, and delivering products to consumers or other enterprises. It pertains to the sales of products (outside the firm), or the movement of items from the manufacturing line to the final consumer.

Outbound and inbound logistics operate together, although they each have distinct responsibilities. Raw materials, completed items and supplies are transported from a factory or other distribution route to a warehouse or retail outlet through inbound logistics procedures. To put it another way, outbound logistics is all about getting things to the end-user. Orders are often started at a warehouse and sent from there to their final destination through outbound logistics.

You May Also Like To Read: What is Elastic Logistics? Benefits and How It Works?

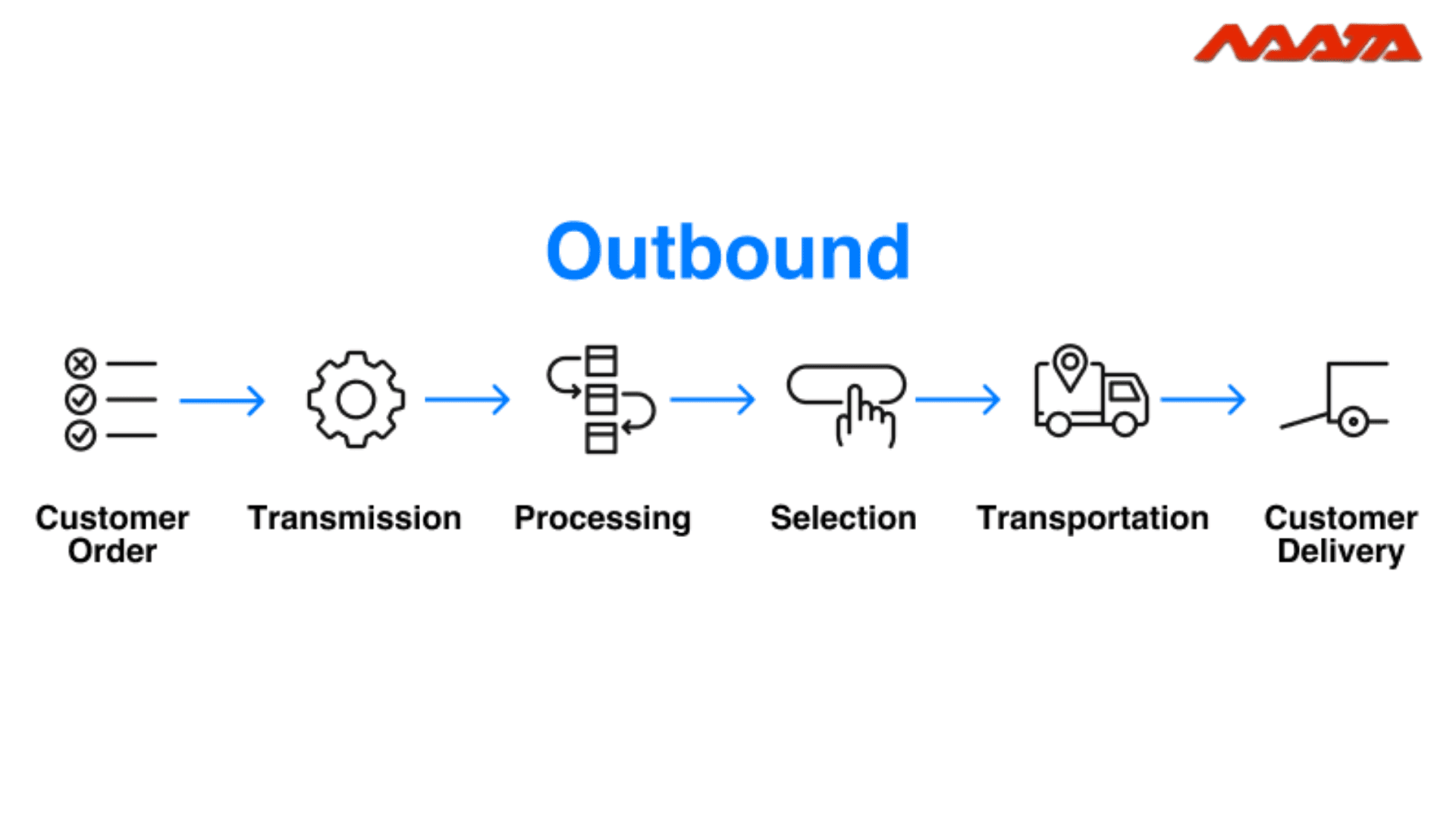

Outbound Process

Outbound logistics involves a number of steps for a company. When a customer places an order, it goes to sales. Checking inventory levels ensures that the order can be fulfilled.

The client order is subsequently sent to the warehouse for selecting and packaging by the sales department. As soon as the order has been sent, a warehouse employee will go through and update inventory levels. The company invoices the customer and receives payment for the order.

You May Also Like To Read: What is Reverse Logistics and It’s Benefits and How It Works

Distribution Channels in Outbound Logistics

Outbound logistics has three primary kinds of distribution channels, each of which includes the product manufacturer, wholesaler, retailer, and consumer. All four types may be found in a single category. Due to the product’s nature or constraints, this may be the best option. As an example, if your firm sells alcoholic beverages, your state’s regulations may stipulate that you must sell them through a wholesaler rather than a retailer.

The wholesaler is eliminated since there is just one middleman in the following channel. Customers buy straight from retailers, who then resell the goods. Large, well-known enterprises who sell their wares to big-box retailers are more likely to use this strategy.

The third route connects the manufacturer of the goods with the person who will use them. A direct-to-consumer approach is often referred to as such. A wholesaler or retailer is not involved in any way. An example of a corporation using this strategy is Apple. They do this by continuing to have flagship locations in shopping centers. Many organizations who use E-commerce also use this channel by directly selling things to customers through their websites.

Cost, speed, quality control, logistical complexity, and customer happiness are some of the most important considerations when selecting a distribution route.

Outbound Logistics Activities

Warehouse Management

As demand increases, a corporation keeps an adequate supply of inventory on hand. The proper storage and organisation of these products is the responsibility of the outbound logistics procedures. During the warehouse management process, inbound and outgoing logistics may run into one other. Inbound logistics pertain to a company’s procurement of completed goods while outbound logistics pertain to the sale of those goods to the end consumer. To put it simply, inbound and outbound logistics refer to the procurement of products and the distribution of those products to customers or retail outlets.

Inventory Management

The primary goal of inventory management is to ensure that items are stored in a manner that preserves their quality and prevents spoiling and damage. Order selection and packaging may be made easier if the correct outgoing warehouse location is found.

Last-mile delivery

It’s possible to describe shipping strategy as a transportation plan that encompasses a bigger network to support deliveries and pickups, but the last-mile delivery strategy is more specific to the supply chain’s outbound logistics procedures.

When it comes to final-mile logistics, everything from route planning and optimization to fleet management and real-time vehicle monitoring — as well as Proof of Delivery — is included.

Last-mile delivery software is used by companies to manage outbound logistics, which includes all of the final-mile delivery operations. A last-mile technology is used to automate and improve the last phases of distribution, from arranging shipments from different warehouses and storage facilities to providing real-time delivery alerts to clients.

Transportation

Based on the final items’ kind, transportation modes and techniques are determined. Outbound transportation of perishable goods, for example, requires specialised trucks.

You May Also Like To Read: 4 Modes of Transportation – Best Way of Moving Your Cargo

Customer service

Outbound logistics must serve consumers first and foremost, and the company as a whole as an extension of that, when it comes to real-time delivery alerts and live monitoring. Logistics must be customer-centric since the success of distribution is based on how quickly and effectively completed items are delivered to consumers.

Because software and solutions that allow automation are used for both inbound and outbound logistics, businesses may keep costs low while still providing high levels of customer satisfaction by being customer-centric. A good example of a service that can be implemented by any company with little input from IT is automated delivery notifications.

Outbound logistics is where customer centricity adds the greatest value to the company, although customer centricity is advantageous at every stage of the supply chain.

Powered By 360PRESENCE

You May Also Like To Read: Three Types of Electric Transportation in one Vehicle – Renault Trucks Unveils e-Mobility Concept