Just-In-Time Inventory (JIT)- Definition, Pros & Cons of JIT

Table of Contents

Just-In-Time Inventory (JIT)

When it comes to inventory management, the just-in-time (JIT) inventory system is a technique that matches raw-material orders from suppliers directly with production schedules. These inventory strategies are used by businesses to boost efficiency and minimise waste by acquiring items just when they are required for the manufacturing process, which decreases inventory expenses. This strategy requires precise demand forecasting on the part of manufacturers.

With just-in-time inventory, you can guarantee that you have enough inventory to manufacture just what you need, when you need it. Aiming for high volume manufacturing while keeping inventory to a bare minimum and eliminating waste is the objective.

JIT inventory guarantees that there is just the correct quantity of inventory to manufacture just what you need, when you need it by keeping inventory levels at a constant level. In order to attain high production volumes with low inventory on hand, it is necessary to increase efficiency while simultaneously minimising waste.

Many organisations have embraced just-in-time inventories in order to save money and remain competitive in the marketplace.

What's The Reasoning Behind Using JIT Inventory ?

It has been asserted by certain businesses that “Inventory means death.” In other words, the firm will not be able to survive if it has an excessive amount of inventory on hand. If the excess resources are not sold or utilized within a reasonable amount of time, they might have a catastrophic impact on the financial health of the organization.

Inventory indicates a financial commitment of working capital that might be better used elsewhere in the organization. Because of an inflexible supply chain that is burdened by long-lead orders and overflowing warehouses, the firm is unable to adapt to shifting market conditions and new prospects.

Because producers do not have to pay to store their goods, just-in-time manufacturing technologies help to reduce inventory expenses. In addition, manufacturers are not left with unsold inventory if an order is canceled or not completed as expected.

By minimizing overhead costs, the purpose of adopting JIT inventory management is to increase a company’s operational profit while simultaneously lowering costs.

You Might Also Like To Read: Inventory Management Techniques: 5 Effective Methods

How Does Just In Time Inventory Work ?

JIT inventory systems are used to reduce inventory while simultaneously increasing overall efficiency. Inventory expenses are reduced in JIT manufacturing systems because producers acquire materials and components only when they are required for production and do not have to pay storage fees.

In addition, manufacturers are not left with unsold inventory if an order is canceled or not completed as expected.

Using a just-in-time inventory strategy, a vehicle manufacturer may operate with minimal inventory levels while placing a heavy reliance on its supply chain to provide the components required to produce automobiles on an as-needed basis. As a result, the manufacturer only orders the components necessary to construct the automobiles after an order has been received.

You Might Also Like To Read: ABC Inventory Management: Definition, Pros & Cons

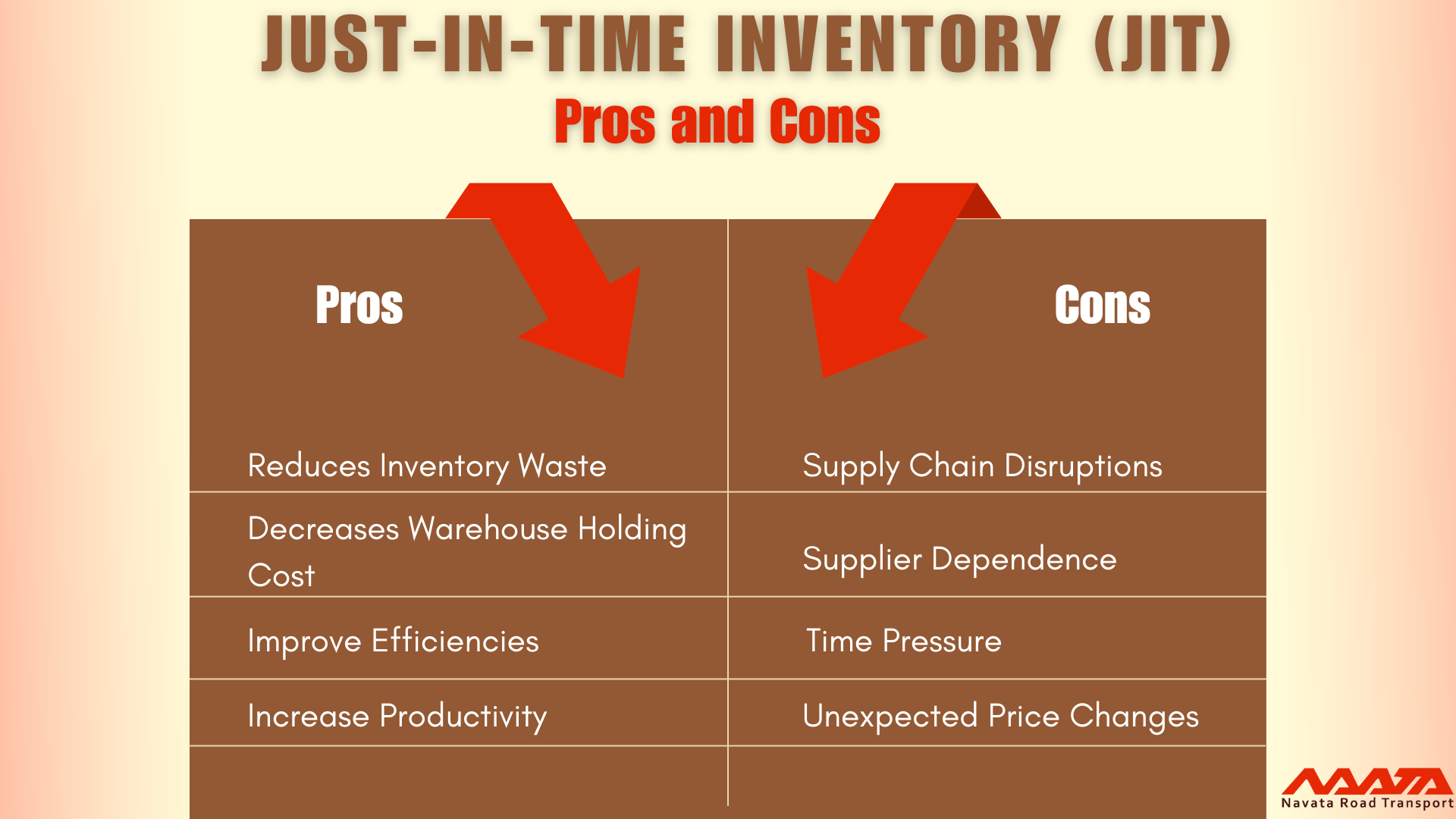

Pros & Cons of Just-In-Time

Pros of JIT

Just in time delivery requires meticulous planning of the whole supply chain, as well as the use of better software, in order to complete the entire process from start to finish, increasing efficiency and reducing the possibility of mistake since each phase is monitored. Here are a few of the most significant consequences of implementing a just-in-time inventory management system:

Reduces Inventory Waste

A just-in-time approach avoids overproduction, which occurs when the supply of a certain item in the market exceeds the demand, resulting in a buildup of unsalable stocks in the warehouse. These unsalable items end up in inventory dead stock, which increases waste and takes up valuable storage space in the warehouse.

When you use a just-in-time system, you only order what you need, eliminating the danger of stockpiling useless goods.

Decreases Warehouse Holding Cost

Warehousing is costly, and having too much inventory may cause your holding expenses to quadruple. The warehouse holding expenses are maintained to a bare minimum in a just-in-time delivery system. Because you only order when a consumer puts an order, your item is already sold by the time it reaches you, eliminating the need to have your things on hand for an extended period of time.

Just-in-time inventory models allow businesses to minimise the quantity of things stored in their warehouses or perhaps remove the need for warehouses completely, reducing costs and increasing efficiency.

Improve Efficiencies

The procurement, management, and storage of extra raw materials and inventories are all reduced under the JIT approach. Increased inventory turnover means that your warehouse won’t be overflowing with outmoded goods.

By receiving and storing supplies in the lowest feasible numbers, surplus raw material stocks may be nearly eliminated. To guarantee timely delivery and reduce the need for safety stock, local sourcing ensures that your suppliers are situated near your company’s manufacturing facilities.

Increase Productivity

JIT inventory management improves production efficiency by minimising the amount of time and resources needed. This allows for more efficient manufacturing and shorter production runs. ‘ As there is less raw material in stock, you may execute product modifications more rapidly. Due to lowered inventory levels, product damage is also minimised.

You Might Also Like To Read: Economic Order Quantity (EOQ): Definition, Pros & Cons

Cons of JIT

For JIT inventory management to work, it has to be able to rely on accurate forecasts and good working relationships with suppliers. There are no backup plans in place if any of those fail. This is an issue.

Potential Risks of Just-in-Time Inventory

JIT’s mindset is the biggest source of risk. JIT inventory management requires the cooperation and commitment of everyone in the ecosystem and supply chain. The whole infrastructure might be at jeopardy if any portion of the system fails.

Lack of Preparedness

The company’s whole process must be restructured in a lean way. It is important to note that these activities have an impact on the business and the supply chain.

Supply Chain Disruptions

It is possible for the manufacturing process to be halted by supply chain issues.

Missed Opportunities

A corporation may not be able to satisfy large and unexpected requests instantly if it has few or no completed items on hand.

Unexpected Price Changes

The cost of components is fixed in JIT. Profit margins decrease as expenses grow.

Overreliance on Forecasts

As a result of the emphasis on predicting, it is difficult to adapt to rapid surges or drops.

Order Issues

Stock-outs and shortages may cause havoc with inventory management systems.

Local Sourcing Costs

A variety of factors contribute to the cost of JIT’s local sourcing. It’s possible that a company’s desire for dependability is affecting its bottom line.

Time Pressure

When it comes to scheduling, there is no assurance that a firm will always be able to get the cheapest pricing from a supplier for raw materials.

Undisciplined Staff

Non-JIT-adherent employees of your team might have a negative impact on your productivity, quality, and other factors.

Supplier Dependence

Production might be halted completely if a supplier fails to deliver on schedule and in the correct quantities.

Unpredictable Events in Nature

Production may be halted if a natural catastrophe disrupts the supply of products from a vendor.

Thanks For Reading: Just-In-Time Inventory (JIT)- Definition, Pros & Cons

Powered By 360Presence