Economic Order Quantity (EOQ): Definition, Pros & Cons

Table of Contents

Economic Order Quantity Inventory Management (EOQ)

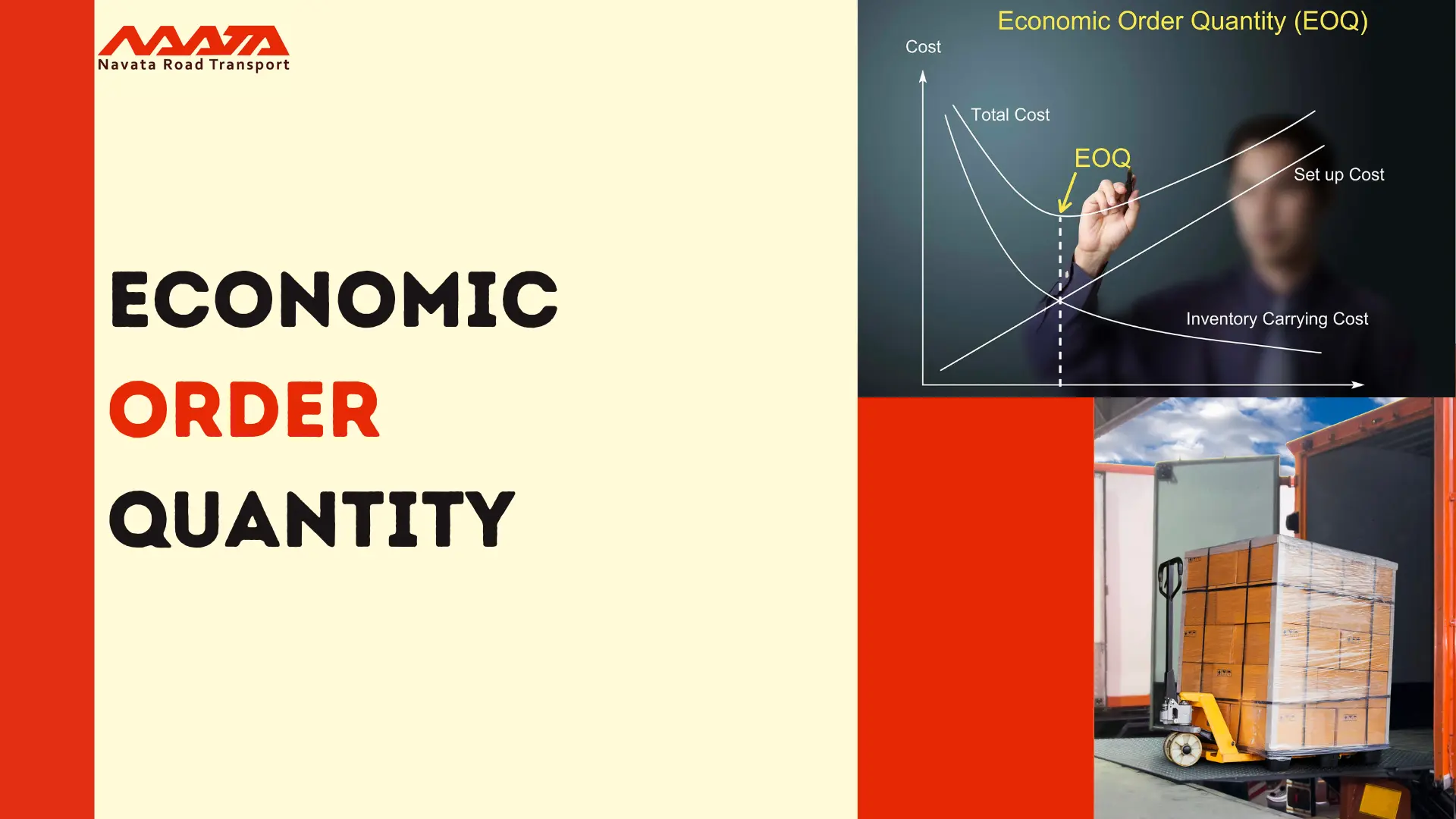

Economic Order Quantity (EOQ) is a widely used inventory management technique that helps businesses determine the optimal order quantity for a particular item while minimizing the total inventory costs.

The primary goal of EOQ is to balance the costs associated with ordering and holding inventory. EOQ is particularly useful for businesses that want to strike a balance between keeping adequate stock levels to meet customer demand and minimizing the costs associated with holding excess inventory.

It’s important to note that while EOQ is a valuable tool for optimizing inventory management, it makes certain simplifying assumptions that may only hold in some situations.

You Might Also Like To Read: Inventory Management Techniques: 5 Effective Methods

How Does Economic Order Quantity Inventory Management Work?

Economic Order Quantity (EOQ) inventory management works by helping businesses determine the optimal order quantity for a particular item, balancing the costs associated with ordering and holding inventory. Here’s how EOQ works in practice:

Gather Relevant Information

- Demand (D): Determine the annual demand for the product. This is the quantity of the product that your business expects to use or sell in a year.

- Ordering Costs (S): Calculate the cost incurred each time an order is placed. This includes administrative costs, transportation costs, and other expenses related to the procurement process.

- Holding Costs (H): Determine the annual holding cost per unit of inventory. This includes expenses like warehousing, insurance, and the opportunity cost of tying up capital in inventory.

- Unit Cost: Know the cost of each unit of inventory.

Calculate EOQ

Use the EOQ formula to find the optimal order quantity:

EOQ = √((2 * D * S) / H)

- EOQ: Economic Order Quantity

- D: Annual demand for the product

- S: Ordering cost per order

- H: Annual holding cost per unit

Determine Reorder Point

To maintain inventory at the optimal level, calculate the reorder point. The reorder point ensures that you place an order when the stock reaches a specific group to avoid stockouts. It is determined using the formula:

Reorder Point = (D / 365) * Lead Time

- D: Annual demand

- 365: The number of days in a year

- Lead Time: The time it takes for an order to be delivered

Continuous Monitoring

Implement a continuous review system. Regularly monitor the inventory levels. When the inventory level reaches or falls below the reorder point, initiate an order for the EOQ.

Safety Stock

Consider the need for safety stock, which is additional inventory held to account for demand variability and lead time variability. Safety stock helps prevent stockouts during unexpected surges in demand or longer-than-expected lead times.

Cost Optimization

EOQ aims to minimize the total cost of inventory, which is the sum of ordering costs and holding costs. By using EOQ, businesses can optimize their inventory management strategy, striking a balance between minimizing the costs of collecting too frequently and maintaining excess inventory.

Batch Ordering

EOQ typically results in batch ordering, in which more significant amounts are requested less frequently. This can lead to cost reductions in cost containment. However, it is critical to ensure that you have enough storage space.

Regular Review

Keep in mind that business conditions change, so it’s essential to review and adjust your EOQ calculations regularly to account for fluctuations in demand, costs, and other variables.

Read About: Just In Time Inventory

Pros of Economic Order Quantity Inventory Management Work

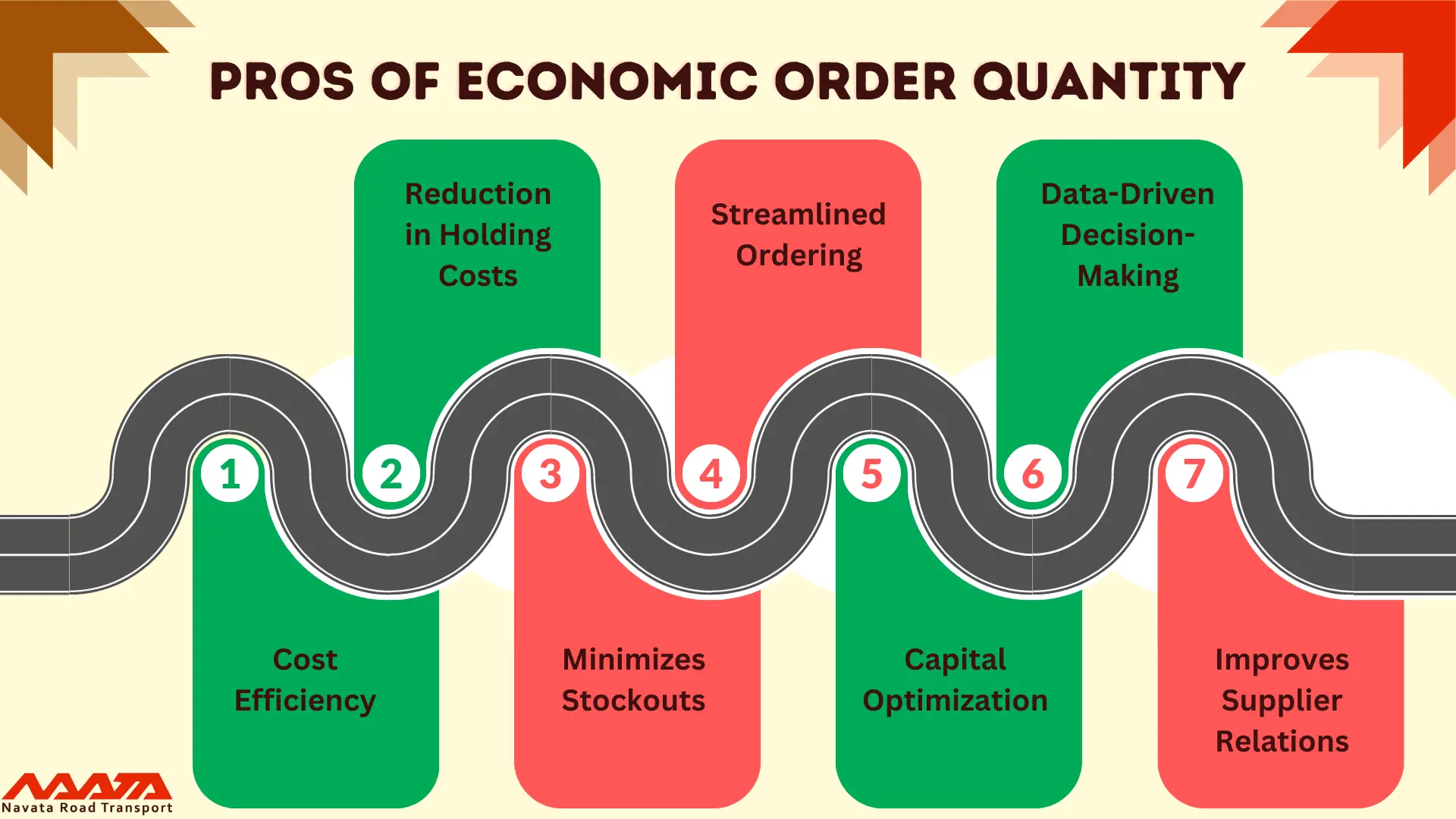

Cost Efficiency

EOQ helps minimize total inventory costs by finding the optimal balance between ordering costs and holding costs. This can lead to cost savings for the business.

Reduction in Holding Costs

EOQ helps in reducing holding costs by ordering the right quantity at the right time, thus avoiding overstocking.

Minimizes Stockouts

By using the reorder point calculated with EOQ, you can ensure that you have enough stock to meet customer demand, reducing the risk of stockouts.

Streamlined Ordering

EOQ promotes batch ordering, which can lead to fewer orders with larger quantities, simplifying the procurement process.

Capital Optimization

By minimizing holding costs and avoiding overstock, EOQ helps optimize the allocation of capital, ensuring it is not tied up in excess inventory.

Data-Driven Decision-Making

EOQ relies on quantitative calculations, which means decisions are based on data and not solely on intuition or guesswork.

Improves Supplier Relations

Consistent, well-planned orders can lead to better relationships with suppliers, potentially resulting in more favorable terms and discounts.

Cons of Economic Order Quantity Inventory Management Work

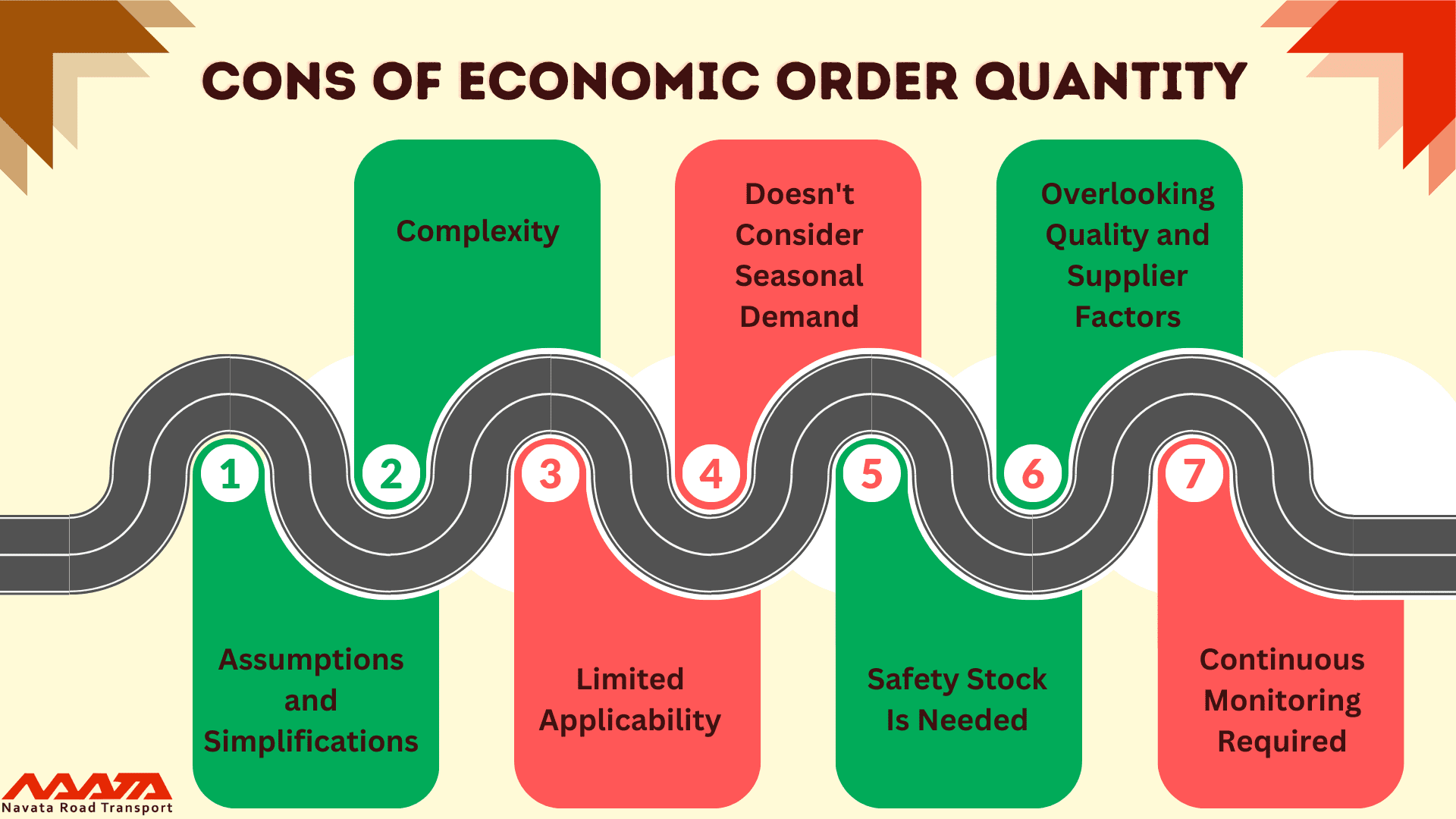

Assumptions and Simplifications

EOQ relies on several assumptions, such as constant demand and holding costs, which may only sometimes hold true in real-world scenarios. Deviations from these assumptions can lead to suboptimal results.

Complexity

Calculating EOQ can be complex and time-consuming, especially for businesses with numerous products and changing variables.

Limited Applicability

EOQ is best suited for products with stable demand patterns. For items with highly variable demand or unpredictable lead times, EOQ may be less effective.

Doesn’t Consider Seasonal Demand

EOQ needs to account for products with seasonal demand patterns, which might require different ordering strategies.

Safety Stock Is Needed

EOQ does not provide a solution for sudden changes in demand or supply disruptions. Safety stock is often required, adding complexity to the inventory management process.

Overlooking Quality and Supplier Factors

EOQ focuses primarily on cost optimization and may manage other factors, such as product quality, vendor reliability, or ethical considerations.

Continuous Monitoring Required

To fully benefit from EOQ, inventory levels need to be regularly monitored, and orders need to be placed when the reorder point is reached. This can be time-consuming and requires ongoing attention.

Thanks For Reading: Economic Order Quantity (EOQ): Definition, Pros & Cons