Sign up for exclusive offers and updates

Let Us Help You Find a Solution That Meets Your Needs.

ABC inventory management, also known as ABC analysis or ABC classification, is a strategy used in supply chain management and inventory control to categorize things into three groups depending on their importance and value to an organization. These are the groups:

The purpose of ABC inventory management is to help organizations allocate resources, time, and attention more effectively based on the relative importance of different items in their inventory. By categorizing items into A, B, and C categories, businesses can focus their efforts on the most critical items while allocating fewer resources to less important items. This approach allows for better inventory control, cost reduction, and improved overall efficiency.

You Might Also Like To Read: Inventory Management Techniques: 5 Effective Methods

ABC inventory management categorizes items in a company’s inventory into three distinct groups (A, B, and C) based on specific criteria. The goal is to prioritize and manage items more effectively according to their importance and value to the business. Here’s how ABC inventory management works:

How to calculate ABC classification?

Gather data about each item in the inventory. The data can include factors such as the item’s usage, annual sales value, cost, profit margin, and other relevant metrics.

Determine the criteria by which items will be classified into the A, B, and C categories. The most common standards are:

Sort and classify each item in the inventory based on the chosen criteria. For example, if the criteria are annual sales value, you might categorize the top 20% of items as A items, the next 30% as B items, and the remaining 50% as C items.

Implement different inventory management strategies for each category:

Periodically review and update the categorization of items. As market conditions change, item performance fluctuates, or business priorities evolve, items may need to be reclassified.

You Might Also Like To Read: Just In Time Inventory – Definition, Pros & Cons of JIT

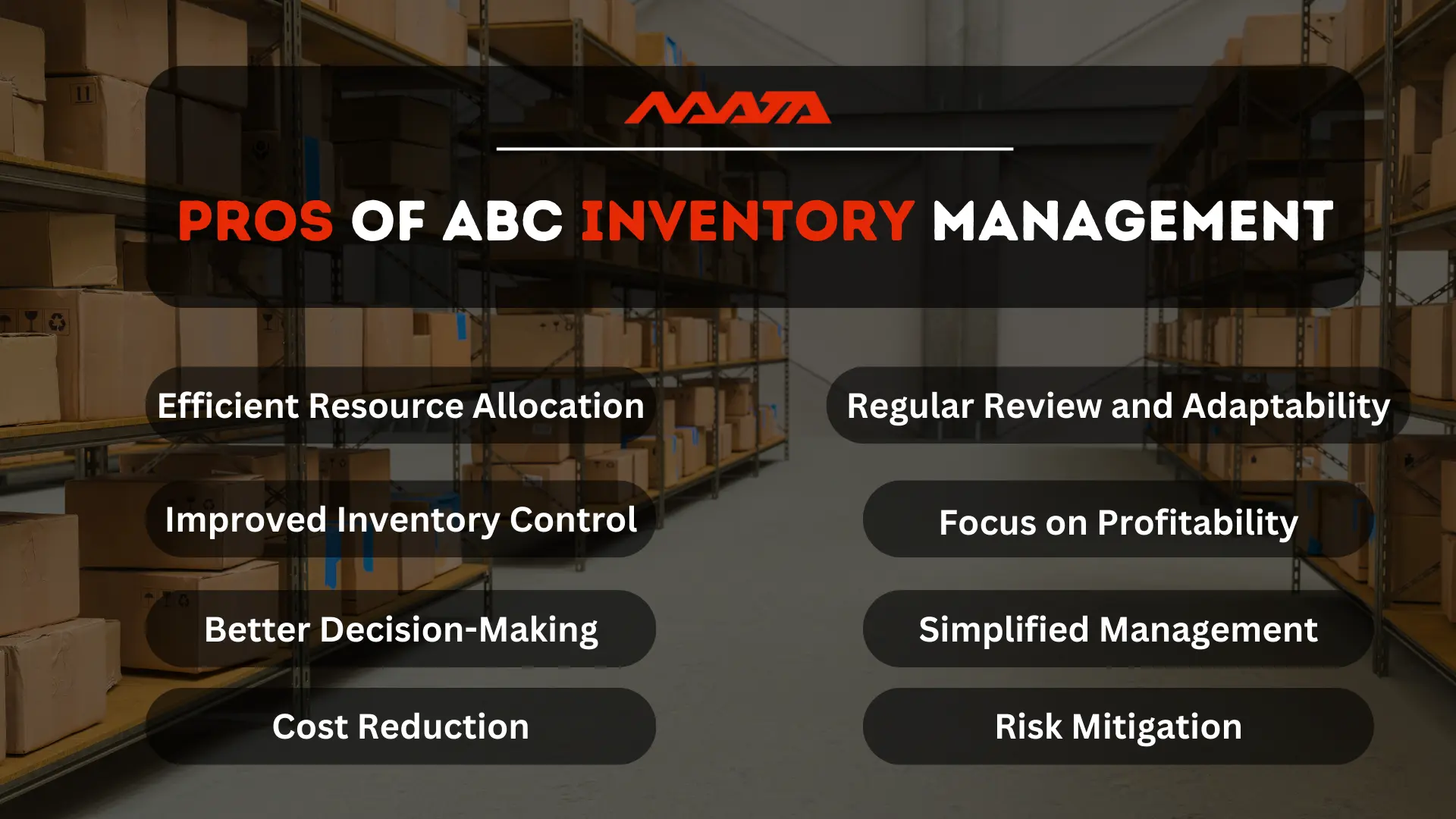

ABC (Always Better Control) inventory management offers several advantages for businesses that adopt this approach. Some of the key benefits and pros of ABC inventory management include:

ABC analysis allows for the efficient allocation of resources, time, and effort. By categorizing items based on their importance and value, companies can focus their attention and resources on the most critical items (A items) and allocate fewer resources to less important items (B and C items).

One of the primary advantages of ABC inventory management is cost reduction. Businesses can optimize inventory levels for each category. A items, being the most critical, might warrant higher safety stock levels, while C items may be kept at minimal levels. This leads to reduced carrying costs, lower storage expenses, and decreased capital tied up in inventory.

ABC analysis enhances control over inventory. By closely monitoring A items and implementing tighter controls, companies can reduce the likelihood of stockouts and better meet customer demand. Simultaneously, the approach helps minimize overstocking of less important items.

ABC categorization provides valuable data for informed decision-making. It helps in determining reorder points, reorder quantities, and stocking levels. This data-driven decision-making improves the accuracy of inventory management and can lead to increased profitability.

ABC inventory management emphasizes the importance of profit. A items, which represent the most profitable items, receive special attention and are managed to maximize returns. This can positively impact the company’s bottom line.

By closely monitoring and managing A items, a business can mitigate the risks associated with running out of stock for critical, high-demand products. This helps maintain customer satisfaction and prevents potential lost sales.

Categorizing items into three groups simplifies inventory management. It streamlines the process by allowing managers to apply distinct strategies for each category rather than treating all items equally.

ABC analysis is not static. It encourages regular reviews of inventory categorization, which helps the system adapt to changing business conditions, shifts in customer demand, or fluctuations in market conditions.

The categorization process increases the transparency of inventory. It allows managers and stakeholders to easily identify which items have the most significant impact on the business’s overall performance.

By ensuring that high-demand or high-profit items (A items) are well-stocked, businesses can improve customer satisfaction and loyalty.

You Might Also Like To Read: Economic Order Quantity (EOQ): Definition, Pros & Cons

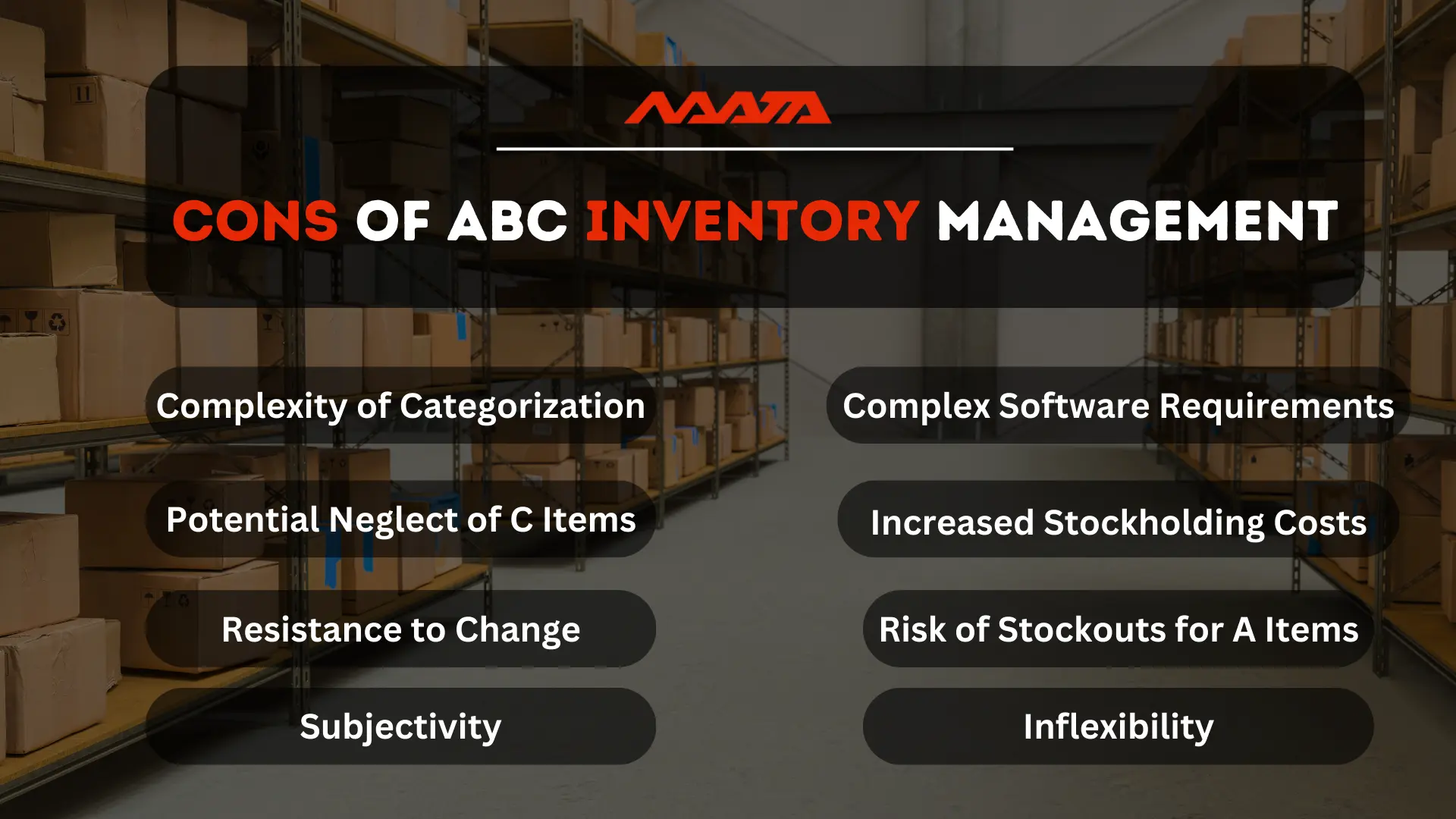

ABC (Always Better Control) inventory management has several advantages, as previously mentioned, but it also comes with some potential drawbacks and cons that businesses should consider when implementing this approach:

The process of categorizing items into A, B, and C groups can be complex and time-consuming. Determining the criteria for categorization and regularly reviewing the classifications can require significant effort.

The choice of criteria and the categorization process can be somewhat subjective. Different individuals or teams within the organization may have varying opinions on how to classify items, which could lead to inconsistencies.

While the focus is often on A items, there is a risk of neglecting C items. These items, though individually less valuable, can collectively represent a significant portion of inventory costs. Ignoring them completely could lead to inefficiencies.

The categories created by ABC analysis are only sometimes adaptable to rapidly changing market conditions. A category can quickly change due to shifts in demand or market dynamics, and businesses need to be prepared to adjust their strategies accordingly.

ABC analysis often relies on factors like annual sales value or cost to categorize items. This can overlook the long-term strategic importance of certain items, such as products with high potential growth in the future.

While the goal is to maintain adequate inventory levels for A items, there is a risk of overstocking, which can tie up capital and lead to obsolescence. Balancing this risk is crucial.

Implementing and maintaining ABC inventory management often requires specialized inventory management software to track and analyze data effectively. This can be costly and may require staff training.

Regularly reviewing and updating the categorization of items and managing inventory levels according to the ABC approach can result in increased administrative overhead.

Simplifying inventory management by grouping items into just three categories can lead to the oversimplification of a complex inventory system. In some cases, businesses may need more nuanced categorization.

Employees and management may resist changes to existing inventory management practices, especially if they have been in place for a long time. Implementing ABC analysis may require a cultural shift within the organization.

ABC analysis is most commonly associated with retail and manufacturing. It may be less applicable or practical in other industries where inventory management is less straightforward.

While ABC analysis can reduce carrying costs for C items, it may increase stockholding costs for A items due to the maintenance of higher safety stock levels.

Thanks For Reading: ABC Inventory Management: Definition, Pros & Cons

Let Us Help You Find a Solution That Meets Your Needs.

Navata Road Transport, a road logistics service provider, established in the year 1982, now occupies a place of pride among the leading Road Transport Organizations in India. Navata is spread across a network of 668 branches in Andhra Pradesh, Telangana, Karnataka, Tamil Nadu, Odisha, Pondicherry, Maharashtra, Gujarat and Madhya Pradesh with ambitious further expansion plans pan India.

Navata Road Transport

D.NO.18-667, BOSE BUILDINGS,

KANURU, VIJAYAWADA – 520007

ANDHRA PRADESH.