Digital Transformation in Logistics: From Manual Operations to Smart Mobility

Table of Contents

Digital Transformation in Logistics

The logistics sector is in the middle of its most significant evolution in decades.

What once ran on paperwork, phone calls, and reactive decision-making is now driven by data, automation, and intelligent connectivity.

This transformation — from manual operations to smart mobility — is redefining how goods move, how fleets operate, and how logistics companies compete.

Digital transformation isn’t about replacing people with machines. It’s about replacing guesswork with insight, fragmented systems with integration, and delayed visibility with real-time intelligence.

You May Also Like to Read: Automation In Supply Chain Management

The Manual Past: Where Logistics Once Stood

Traditional logistics relied heavily on manual processes — handwritten records, static route sheets, and human coordination across long, uncertain supply lines.

Each stage of movement was managed separately: dispatchers tracked vehicles manually, warehouses worked with isolated systems, and customers had limited visibility into their orders.

The result was predictable:

- High administrative overhead

- Frequent communication delays

- Limited visibility into costs and fleet health

- Reactive issue handling instead of proactive management

In short, logistics operated — but it didn’t learn.

The Digital Present: Transformation in Action

Today, that manual backbone has been replaced by digitally synchronized networks.

Transformation is visible across every level of logistics:

Warehousing:

Automated WMS systems powered by robotics and IoT now handle real-time inventory tracking, barcode scanning, and AI-led picking. Warehouses no longer store goods — they process data.

Fleet Management:

Connected vehicles use telematics, GPS, and predictive analytics to track performance, maintenance schedules, and driver behavior. Fleet operators can now reduce idle time and fuel waste by analyzing live insights.

Transport Planning:

AI-driven route optimization systems calculate the most efficient paths based on live traffic, weather, and demand — improving delivery times while cutting emissions.

Last-Mile Delivery:

Digital proof of delivery, mobile tracking apps, and customer notification systems are standard practice — improving transparency and satisfaction.

This integration marks the first full-scale shift from manual coordination to connected ecosystems.

How Smart Mobility Works?

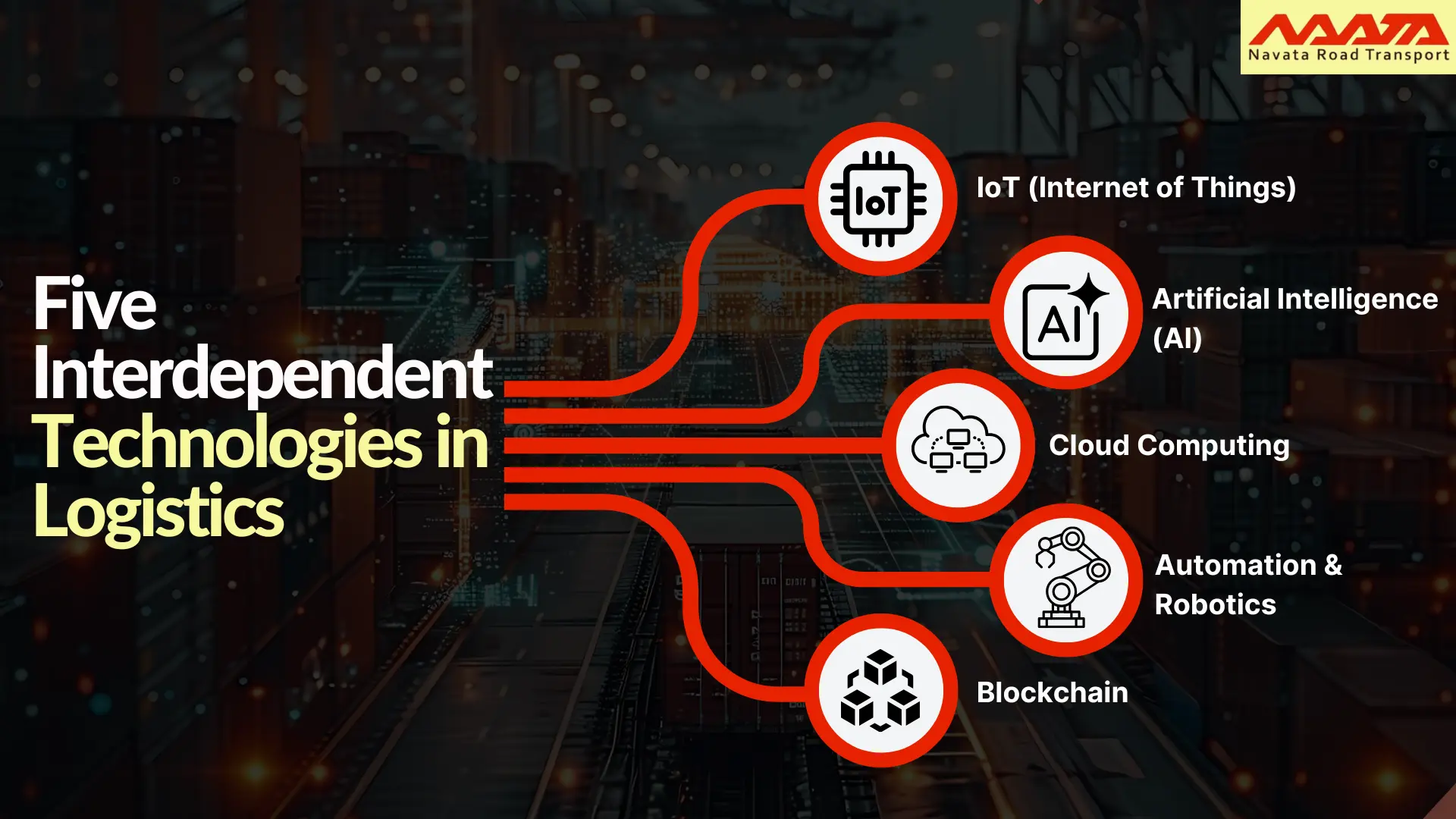

The digital backbone of logistics transformation runs on five interdependent technologies:

- IoT (Internet of Things): Embeds sensors in vehicles, containers, and cargo — generating live operational data.

- Artificial Intelligence (AI): Turns raw data into predictive insights for demand, maintenance, and route planning.

- Cloud Computing: Connects dispersed teams, fleets, and partners on a unified digital platform.

- Automation & Robotics: Streamline warehousing, reduce human error, and improve turnaround speed.

- Blockchain: Enables secure, tamper-proof data sharing across shippers, carriers, and customers.

Together, these technologies form the smart mobility ecosystem — where data flows continuously from ground to cloud and back to operations.

Read More About: What is Blockchain Technology in Transportation?

Where It’s Happening?: The Real-World Impact

Digital transformation is not theoretical — it’s visible in measurable performance gains:

- Fuel Efficiency: Real-time route optimization has reduced fleet fuel consumption by up to 15–20%.

- Downtime Reduction: Predictive maintenance powered by telematics reduces unexpected breakdowns by 30–40%.

- Faster Turnarounds: Automated loading/unloading systems improve warehouse throughput by 25–35%.

- End-to-End Visibility: Shippers now track goods across multimodal routes with 99% accuracy.

Smart mobility transforms logistics from a reactive, fragmented system into a predictive, responsive network.

From Smart Mobility to Predictive Logistics

The next frontier of logistics transformation lies in predictive intelligence.

AI algorithms now analyze historical shipment data, fuel usage, and route performance to predict future disruptions — from traffic congestion to vehicle wear.

Autonomous vehicles and drones are emerging as the next extension of smart mobility, reducing dependency on manual driving and enabling continuous delivery cycles.

In this ecosystem, mobility isn’t just smart — it’s self-optimizing.

Impact: Efficiency, Sustainability, and Competitiveness

Digital transformation is reshaping the logistics landscape in three major ways:

- Operational Efficiency: Automated scheduling and live tracking reduce human intervention and errors.

- Sustainability: Optimized routes and reduced idle time lower carbon emissions significantly.

- Customer-Centricity: Real-time updates and predictive ETAs enhance service trust and brand loyalty.

For logistics providers, digital transformation is no longer a choice — it’s the foundation for competitiveness in a connected, time-sensitive economy.

Conclusion

The journey from manual operations to smart mobility isn’t just technological — it’s strategic. Companies that digitize their logistics gain control, agility, and foresight. Those that don’t risk being left behind in an industry where speed, accuracy, and data define success.

Digital transformation is turning logistics into an intelligent mobility network — one that learns, predicts, and delivers with precision.

The future of logistics isn’t just digital — it’s decisively smart.

Thank You For Reading: Digital Transformation in Logistics: From Manual Operations to Smart Mobility

Powered By 360Presence