Trucking Management and Automation: Navigating the Future of Road Transportation

Table of Contents

Trucking Management and Automation

The road transportation industry, constantly grapples with a fundamental challenge: How can we save on road transportation costs without compromising on supply chain responsiveness? This question plagues most companies involved in freight movement. While the generic advice often points towards “using technology,” the ensuing confusion around implementation often leads companies down paths that don’t fully harness technology’s true potential.

Many businesses resort to one of four common approaches, each with its own set of limitations:

Bidding Platforms: While offering lower initial costs, these platforms often lack holistic intelligence, failing to provide a comprehensive view of operations or long-term strategic benefits for trucking fleet management.

In-House Platform Development: Building a proprietary system requires significant upfront costs and ongoing managerial time for development, maintenance, and upgrades, often diverting resources from core business activities.

Outsourcing Custom Platforms: Collaborating with third parties unfamiliar with logistics industry dynamics, or specialists in only a few technologies, can lead to multiple iterations, less optimal technology use, and difficulties integrating new solutions.

Disparate Trucking Management Systems: Using separate systems for tracking, RFP management, and accounting for shipments creates silos, resulting in low productivity, reduced accuracy, and critical blind spots in overall operations.

All these options often fail to provide a bird’s-eye view of the entire operation in one place. Moreover, they are either prohibitively costly, highly inefficient, or, in many cases, both. The answer, however, lies in a more integrated and comprehensive approach: Trucking Management and Automation.

You May Also Like to Read: What is Supply Chain Management

Power of Automation Software in Logistics

Automation software, often delivered as cloud-based SaaS solutions, is revolutionizing the logistics and transportation sector. These solutions automate workflows, streamline management, and provide unprecedented visibility. While generalized software options are emerging, many commercial companies still opt for custom solutions due to the unique nuances of their operations.

However, various specialized software solutions are being adopted across different departments within logistics. Key departments include:

Conventional Department: Often utilizes CVT software / CTMS software for general freight management.

Container Trucking: Relies heavily on CTMS software for efficient container movement and tracking.

Warehouse: Benefits immensely from WMS (Warehouse Management Systems) / WCS (Warehouse Control Systems) for optimizing storage, picking, and packing.

Marine Engineering & Heavy Haulage: These specialized areas also increasingly integrate tailored automation tools for complex project management and asset utilization.

Trucking Automation: Beyond Basic Software

While the above highlights departmental software, the concept of Trucking Automation goes deeper, fundamentally transforming how goods are transported by road. It integrates advanced technologies to enhance not just efficiency but also logistics safety, aiming to reduce human dependency significantly.

What is Trucking Automation?

At its core, trucking automation refers to the development and integration of autonomous vehicles equipped with sophisticated sensors, cameras, GPS, and Artificial Intelligence (AI) to navigate roads and execute driving tasks with minimal or no human intervention. The primary goals are clear: enhance safety by mitigating human error, boost efficiency through optimized route planning and continuous operation, and reduce operational costs by potentially decreasing the reliance on human drivers for certain tasks.

The Levels of Trucking Automation

To understand the evolution and capabilities, trucking automation is categorized into several levels based on the degree of human involvement required:

Level 0 (No Automation): The human driver is in complete control of all driving aspects, with no automated assistance.

Level 1 (Driver Assistance): Basic systems like cruise control or lane-keeping assistance support the driver, who remains fully responsible for vehicle control.

Level 2 (Partial Automation): Advanced Driver Assistance Systems (ADAS) enable the vehicle to control both steering and acceleration/deceleration, but the human driver must remain engaged and actively monitor the environment.

Level 3 (Conditional Automation): The vehicle can handle all truck driving tasks under specific conditions (e.g., highway driving), but the human driver must be ready to take over when prompted by the system.

Level 4 (High Automation): The vehicle can operate independently without human input under specific, pre-defined conditions or within designated areas. A human driver is not required to intervene.

Level 5 (Full Automation): The vehicle is fully autonomous in all driving conditions and environments, requiring no human driver at any time.

These levels illustrate the progressive capabilities of automated technologies in the trucking industry, continuously striving for higher safety, efficiency, and reduced human intervention.

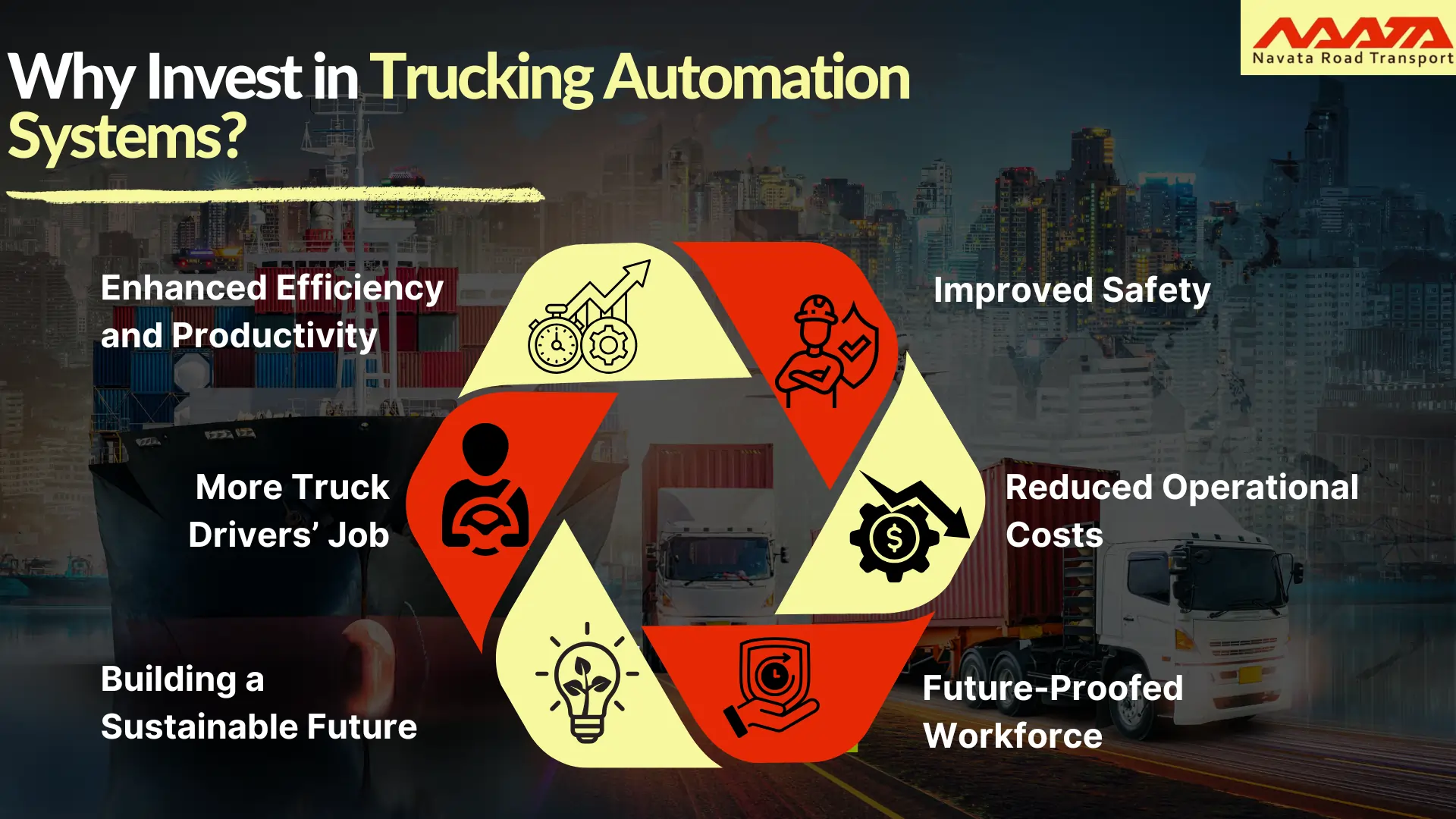

Why Invest in Trucking Automation Systems?

The compelling benefits of trucking automation systems make a strong case for investment:

Enhanced Efficiency and Productivity: Trucking automation enables 24/7 operations, unaffected by human fatigue. Through optimized route planning and real-time traffic analysis, it drastically reduces delays, ensuring faster delivery times and significantly boosting overall productivity across the logistics network.

Improved Safety: Automated trucks, with advanced sensors and AI, react to road conditions quicker than humans. This dramatically lowers accident risks from human error like distraction or fatigue, enhancing safety for drivers, cargo, and all road users.

Reduced Operational Costs: Trucking automation significantly cuts expenses by reducing reliance on a large driver workforce. Consistent driving habits from automated systems also decrease fuel consumption and vehicle wear, leading to substantial savings in maintenance.

Future-Proofed Workforce: Investing in automation prepares your team for the evolving industry. It shifts focus to training employees for new roles in managing and maintaining automated systems, ensuring relevance and retaining invaluable institutional knowledge as technology progresses.

Building a Sustainable Future: Automation in trucking contributes to environmental sustainability. Autonomous trucks optimize fuel usage and minimize idling, reducing emissions and carbon footprint, thereby supporting global efforts towards a greener transportation sector.

More Truck Drivers’ Job (Transformed Roles): While traditional driving roles may evolve, trucking automation creates new opportunities. It necessitates skills in overseeing autonomous operations, managing integrated logistics, and maintaining high-tech equipment, opening diverse employment avenues within the industry.

You May Also Like to Read: What is Route Optimization Software and Benefits

Improving Effectiveness of Trucking Management Through Automation

The integration of Trucking Management principles with advanced Trucking Automation technologies significantly enhances various aspects of logistics:

Logistical Network Optimization: Automation provides the tools to analyze and optimize the entire network, identifying inefficiencies and opportunities for improvement.

Information Flow: Centralized, real-time data from automated systems eliminates blind spots, providing a holistic view of operations for informed decision-making.

Transportation Efficiency: From dynamic route optimization to autonomous driving, automation directly tackles inefficiencies in transport, leading to faster, safer, and more cost-effective deliveries.

Sound Inventory Management: While directly linked to warehousing, the improved predictability and tracking capabilities brought by automation in transportation also aid in more accurate inventory forecasting and management.

Warehousing, Materials Handling & Packaging: Integrated solutions ensure a smooth flow of goods from warehouse to truck and vice-versa, with automated systems optimizing internal processes.

Practical Steps Towards Trucking Management and Automation

Here are three examples demonstrating how companies can move towards effective trucking management & automation:

1. Streamlining Accounts Receivable Processes for Faster Cash Collections: Managing PODs (Proof of Deliveries), BOLs (Bills of Lading), and other shipping documents is traditionally a paper-intensive process. Each shipment can take days to consolidate, process, verify, and mail, often involving multiple individuals.

Automation: Implementing document scanning and workflow automation software digitizes these documents. Intelligent systems can automatically verify data, generate invoices, and send them electronically. Collections staff then have immediate access to all necessary documents, significantly reducing the time spent chasing payments and improving cash flow.

2. Recruiting & Hiring Drivers (and Fleet Personnel): The industry faces a chronic challenge in recruiting, hiring, and retaining skilled commercial truck drivers. The process is often difficult, expensive, and continuous due to high turnover.

Automation: Driver recruiting software automates and streamlines the entire process.

- Step 1: Driver applies online via mobile-optimized forms.

- Step 2: Recruiters review applications in a centralized portal, ensuring adherence to hiring policies and tracking progress through a structured workflow.

- Step 3: Managers approve hiring decisions using built-in business process automation tools that automatically change statuses, create activities, send notifications, and email attachments internally and externally. This also extends to recruiting for new roles created by automation, such as fleet monitors and maintenance technicians.

3. Processing Safety & Incident Claims: Manually processing claims (accidents, investigations, violations, insurance, Worker Compensation) is complex, inefficient, and often leads to inaccurate data, poor productivity, and mishandled cases.

Automation: An automated process leverages document scanning and imaging software to improve claims management and workflow. Organizations can define processes and rules to handle different document types related to incidents.

Documents are automatically routed to the relevant departments (e.g., Human Resources, Safety, Driver Manager for a Worker Compensation claim), ensuring each participant is promptly advised and has visibility into incident details as they unfold. This leads to quicker resolution, better compliance, and reduced liabilities.

Read More About How Trucking Tracking System Works

Conclusion

The integration of Trucking Management principles with advanced Trucking Automation technologies is not just a trend; it’s the inevitable evolution of the transportation industry. By strategically adopting these solutions, companies can overcome traditional hurdles, achieve significant cost savings, and most importantly, enhance their supply chain responsiveness, ensuring they remain competitive in a rapidly changing world. The future of trucking is efficient, safe, and undeniably automated.

ThankYou For Reading: Trucking Management and Automation: Navigating the Future of Road Transportation

Powered By 360 Presence

Leave a Replay

Trucking Management Automation logistics management and automation transportation Trucking Management Automation logistics management and automation transportation Trucking Management Automation logistics management and automation transportation