Sign up for exclusive offers and updates

Let Us Help You Find a Solution That Meets Your Needs.

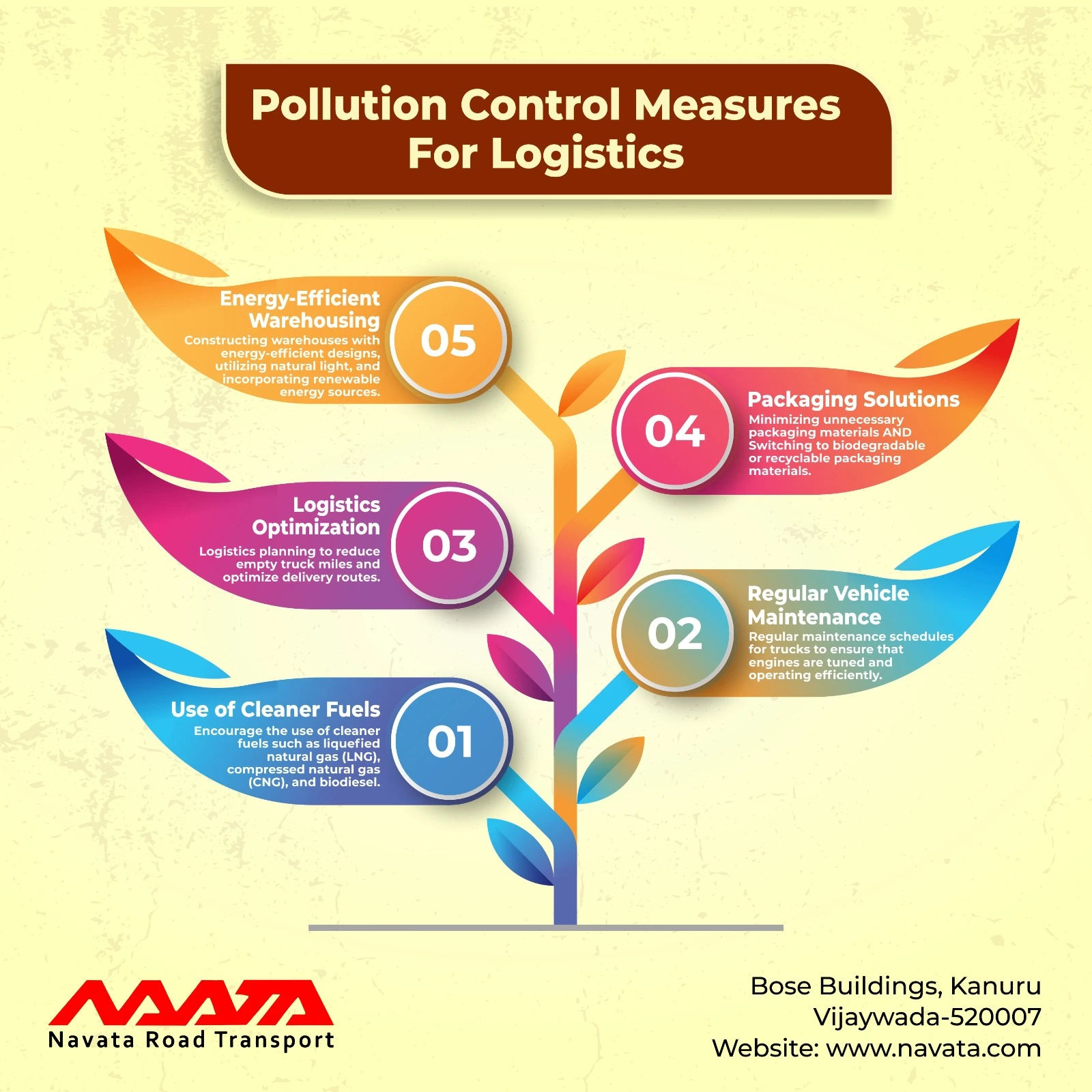

In an era where environmental consciousness is at the forefront of global concerns, the logistics industry plays a pivotal role in shaping a sustainable future. As the demand for efficient transportation and timely delivery grows, so does the environmental impact of logistics operations. However, there is a silver lining – a multitude of pollution control measures that can be implemented to mitigate the ecological footprint of the logistics sector.

Also Read: 5 Steps To Reduce Emissions

The use of cleaner fuels is a crucial pollution control measure in the logistics industry, where the reliance on traditional fossil fuels has been a significant contributor to environmental degradation. Cleaner fuels offer a sustainable alternative, reducing the carbon footprint and minimizing the adverse effects on air quality. Let’s delve deeper into the importance and implementation of cleaner fuels in logistics.

One of the primary benefits of cleaner fuels is their ability to cut down on carbon emissions. Traditional diesel and gasoline fuels release pollutants such as carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter into the atmosphere, contributing to global warming and air pollution. Cleaner fuels, such as biodiesel, compressed natural gas (CNG), and electric power, produce fewer emissions, promoting a healthier and more sustainable environment.

Biodiesel, derived from renewable resources like vegetable oils and animal fats, is a viable alternative to traditional diesel. It is known for its lower carbon content and reduced emission of harmful pollutants. Logistics companies can integrate biodiesel into their fleets without requiring significant modifications to existing diesel engines, making it a practical and eco-friendly option.

CNG is a cleaner-burning alternative to conventional gasoline and diesel. It produces lower levels of carbon emissions and air pollutants, making it an environmentally friendly choice for transportation. Converting logistics vehicles to run on CNG may involve some initial investment in fueling infrastructure and engine modifications, but the long-term environmental benefits make it a sustainable option.

The adoption of electric vehicles in logistics is gaining momentum as technology advances and the charging infrastructure expands. EVs produce zero tailpipe emissions, making them a key player in reducing air pollution. Logistics companies can incorporate electric delivery vans and trucks into their fleets, taking advantage of the growing network of charging stations and government incentives for sustainable transportation.

Hydrogen fuel cells represent another promising avenue for cleaner fuel in logistics. Vehicles powered by hydrogen fuel cells emit only water vapor and heat as byproducts, contributing to zero-emission transportation. Although the infrastructure for hydrogen fueling is currently limited, ongoing research and development are addressing these challenges, paving the way for a more widespread adoption of this technology in the logistics sector.

Regular vehicle maintenance is a critical aspect of pollution control measures in the logistics industry. Ensuring that the logistics fleet is well-maintained contributes significantly to reducing environmental impact, enhancing fuel efficiency, and extending the lifespan of vehicles. Here’s an in-depth exploration of the importance and components of regular vehicle maintenance in the context of pollution control:

Regular maintenance involves routine checks and adjustments to the vehicle’s engine. This includes changing the oil, air filters, and fuel filters. An optimally performing engine burns fuel more efficiently, reducing emissions and fuel consumption. Properly tuned engines also produce fewer pollutants and contribute to a cleaner environment.

Adequate tire maintenance is crucial for fuel efficiency. Underinflated tires increase rolling resistance, requiring more fuel to propel the vehicle. Regular tire rotations and alignments ensure even wear and improved fuel economy. By maintaining proper tire pressure, logistics companies can decrease their carbon footprint and operating costs.

The emission control system of vehicles plays a key role in reducing harmful pollutants released into the atmosphere. Regular checks and maintenance of components such as the catalytic converter and oxygen sensors help ensure that the vehicle meets emission standards. Addressing issues promptly prevents excessive emissions and contributes to cleaner air quality.

Various fluids, including coolant, transmission fluid, and brake fluid, play essential roles in vehicle performance. Regular checks and timely replacements of these fluids prevent engine overheating, transmission malfunctions, and brake system failures. Properly functioning systems are more fuel-efficient and emit fewer pollutants.

In addition to physical maintenance, regular vehicle checkups provide an opportunity to promote eco-friendly driving habits among logistics professionals. Training programs can educate drivers on fuel-efficient driving techniques, such as maintaining a steady speed, avoiding excessive idling, and reducing aggressive acceleration. These practices not only conserve fuel but also minimize emissions.

Logistics optimization is a crucial pollution control measure within the logistics sector that focuses on streamlining operations to minimize environmental impact. This strategy involves the efficient management of resources, routes, and processes to reduce fuel consumption, lower emissions, and enhance overall sustainability. Here’s a detailed explanation of how logistics optimization contributes to pollution control:

Logistics optimization starts with the efficient planning of transportation routes. By leveraging advanced technologies such as GPS, real-time traffic data, and route optimization algorithms, companies can identify the most fuel-efficient and time-saving routes. This not only reduces the carbon footprint by minimizing the distance traveled but also enhances delivery speed and reliability.

Optimizing logistics involves maximizing the capacity of transportation vehicles. Load consolidation aims to combine shipments efficiently, reducing the number of partially filled trucks on the road. By transporting larger quantities in a single trip, companies can lower fuel consumption per unit of cargo, leading to reduced emissions and operational costs.

Utilizing real-time tracking and visibility solutions provides logistics companies with the ability to monitor the location and condition of shipments throughout the supply chain. This enhances overall operational efficiency, allowing for quick responses to disruptions and ensuring that routes are continuously optimized based on live data. The result is a reduction in unnecessary detours and delays, leading to lower fuel consumption.

Logistics optimization relies heavily on data analytics to make informed decisions. By analyzing historical data, companies can identify patterns, optimize inventory levels, and improve overall supply chain efficiency. Data-driven decision-making helps in reducing overstocking, minimizing the need for expedited shipping, and enhancing overall resource utilization, all of which contribute to pollution control.

Energy-efficient warehousing is a critical aspect of pollution control measures within the logistics industry. Warehouses serve as central hubs where goods are stored, sorted, and processed before reaching their final destination. Adopting energy-efficient practices in warehousing not only reduces operational costs but also minimizes the environmental impact of logistics operations. Here’s a detailed explanation of how energy-efficient warehousing contributes to pollution control:

Energy-efficient warehouses prioritize the use of advanced lighting systems, such as LED technology. LED lights consume significantly less energy compared to traditional lighting sources, leading to reduced electricity consumption and lower carbon emissions. Motion sensor lights can also be employed to ensure that lighting is active only in occupied areas, minimizing unnecessary energy use.

Proper insulation is essential to maintain optimal temperature conditions within the warehouse. Well-insulated facilities require less energy for heating or cooling, contributing to energy efficiency. This is particularly crucial for warehouses storing temperature-sensitive goods, as it reduces the reliance on heating, ventilation, and air conditioning (HVAC) systems.

Implementing smart temperature control systems enables warehouses to regulate temperatures more efficiently. These systems can be programmed to adjust heating and cooling based on real-time data, ensuring that energy is used only when necessary. This not only saves energy but also enhances the longevity of stored goods.

Warehouses can transition to sustainable energy sources, such as solar power. Installing solar panels on warehouse rooftops allows the facility to generate clean energy, reducing dependence on traditional power sources. This investment not only aligns with environmental goals but also offers long-term cost savings as the initial setup costs are offset by reduced electricity bills.

Energy management systems enable warehouses to monitor and optimize energy consumption. By collecting and analyzing data on energy usage, these systems identify areas for improvement and implement strategies to enhance overall efficiency. This proactive approach helps in minimizing energy wastage and reducing the warehouse’s carbon footprint.

Packaging plays a crucial role in the logistics process, ensuring that goods are transported safely from point A to point B. However, traditional packaging methods often contribute significantly to environmental pollution. To address this issue, implementing sustainable packaging solutions is an essential pollution control measure in the logistics industry. Let’s delve deeper into the significance and strategies of sustainable packaging:

Sustainable packaging focuses on minimizing material usage without compromising the integrity of the goods being transported. This can involve using lighter materials, optimizing packaging designs to reduce excess space, and embracing innovative solutions like packaging with air cushions instead of traditional fillers. By reducing material waste, logistics companies can contribute to a decrease in overall environmental pollution.

Choosing packaging materials that are recyclable or biodegradable is a key aspect of pollution control in logistics. Materials like cardboard, paper, and certain types of plastics can be recycled, diverting them from landfills. Biodegradable materials break down naturally over time, reducing the long-term impact on the environment. This shift towards eco-friendly materials is not only beneficial for the planet but also aligns with the growing demand for sustainable practices from consumers.

Embracing the concept of reusable packaging is another strategy to minimize environmental impact. Rather than using single-use materials, logistics companies can invest in durable packaging solutions that can be returned and reused for multiple shipments. This approach not only reduces waste but also lowers the overall demand for new packaging materials, promoting a more circular and sustainable system.

Thanks For Reading: 5 Pollution Control Measures For Logistics

Powered By 360Presence

Let Us Help You Find a Solution That Meets Your Needs.

Navata Road Transport, a road logistics service provider, established in the year 1982, now occupies a place of pride among the leading Road Transport Organizations in India. Navata is spread across a network of 668 branches in Andhra Pradesh, Telangana, Karnataka, Tamil Nadu, Odisha, Pondicherry, Maharashtra, Gujarat and Madhya Pradesh with ambitious further expansion plans pan India.

Navata Road Transport

D.NO.18-667, BOSE BUILDINGS,

KANURU, VIJAYAWADA – 520007

ANDHRA PRADESH.