How to Implement a Warehouse Management System (WMS)?: Step By Step Guide

Table of Contents

How to Implement a Warehouse Management System (WMS)

Implementing a Warehouse Management System (WMS) is a transformative project that reshapes how warehouses operate, from inbound receiving to last-mile delivery. A WMS can boost accuracy, efficiency, and scalability—but implementation requires careful planning, alignment, and execution.

This guide provides a deep, step-by-step roadmap to implement warehouse management system (WMS), highlighting not only the what but the why and how behind each stage, ensuring you avoid costly mistakes and maximize ROI.

You May Also Like to Read: Benefits of Warehouse Automation

Why Implement a WMS?

Warehouses today face challenges like rising order volumes, SKU proliferation, labour shortages, and customer demands for faster delivery. A WMS addresses these pain points by providing:

- Real-time inventory visibility – Track SKUs across zones, bins, and batches.

- Higher fulfilment accuracy – Reduce picking errors by 30–50%.

- Process standardization – From putaway rules to picking methods, eliminate inconsistencies.

- Scalability – Support automation (AMRs, conveyors, sorters) and multi-warehouse operations.

- Data-driven decision-making – Reports on cycle times, inventory turnover, and workforce productivity.

Without a WMS, many businesses plateau in efficiency and struggle to scale.

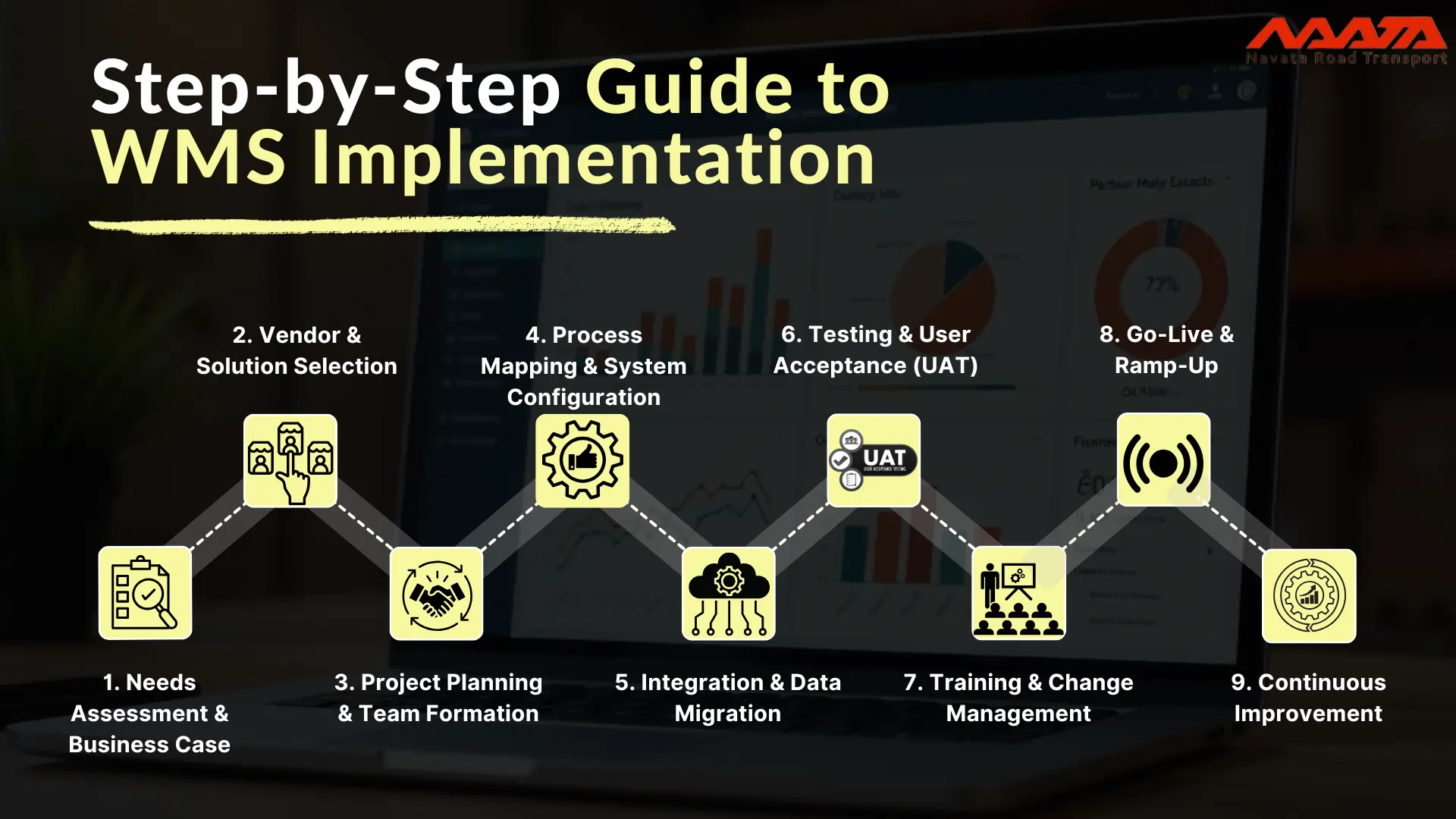

Step-by-Step Guide to WMS Implementation

1. Needs Assessment & Business Case

Why it matters: Without a clear business case, implementations risk scope creep and wasted investment.

Key actions:

- Document current workflows: inbound, putaway, storage, picking, packing, shipping, returns.

- Identify pain points: inaccurate stock, poor space utilization, slow picking, bottlenecks.

- Set KPIs: inventory accuracy (aim for >98%), order fulfilment time, dock-to-stock cycle, labour productivity.

- Calculate ROI: weigh licensing, infrastructure, training, and downtime against expected savings and improvements.

Pro tip: Include both quantitative (cost savings, productivity) and qualitative (customer satisfaction, employee morale) benefits in your business case.

2. Vendor & Solution Selection

Why it matters: Choosing the wrong vendor can lock you into expensive, inflexible systems.

Evaluation checklist:

- Core features: inbound/outbound workflows, returns management, slotting, cycle counting, cross-docking.

- Scalability: Can it handle growth, automation, and multiple warehouses?

- Integration: Seamless links with ERP, TMS, OMS, accounting, and e-commerce platforms.

- Usability: Intuitive UI, mobile-first design for handheld scanners.

- Support & reliability: Local support, uptime guarantees, training programs.

- Deployment model: Cloud vs on-premise—cloud offers faster deployment and scalability, on-premise allows higher customization and control.

Pro tip: Run a pilot project or proof-of-concept to validate how the WMS handles real-world workflows.

You May Also Like to Read: Benefits of Warehouse Management System (WMS)

3. Project Planning & Team Formation

Why it matters: A WMS rollout touches every part of your warehouse—without strong project governance, chaos follows.

Implementation team roles:

- Project manager: Drives timelines, risk management, stakeholder alignment.

- Operations lead: Ensures warehouse processes are reflected accurately.

- IT lead: Manages integrations, infrastructure, and cybersecurity.

- Training coordinator: Oversees staff adoption and readiness.

Planning essentials:

- Timeline with milestones (configuration, integration, UAT, go-live).

- Risk register: identify potential disruptions (data migration, downtime, staff turnover).

- Infrastructure readiness: robust Wi-Fi, handhelds, printers, charging stations.

4. Process Mapping & System Configuration

Why it matters: A WMS should improve operations, not digitize inefficiencies.

Steps:

- Analyse and re-engineer workflows before configuration.

- Define slotting strategies (FIFO, LIFO, FEFO for perishables).

- Configure picking methods: single-order, batch, wave, or zone picking based on volume and layout.

- Set up item master data, bin locations, stock attributes (weight, expiry, hazardous codes).

- Build exception handling: damaged goods, over-receipts, short-picks.

Pro tip: Avoid over-customization. Stick to out-of-the-box features when possible—custom code adds complexity and cost.

5. Integration & Data Migration

Why it matters: A WMS is only as good as the systems it connects with.

Integration focus:

- ERP: Financials, procurement, and inventory valuation.

- TMS: Freight planning, carrier allocation, shipment tracking.

- OMS/E-commerce platforms: Order import/export.

- Automation: Conveyors, sorters, AS/RS, robotics.

Data migration essentials:

- Clean item master data, eliminate duplicates, standardize units.

- Verify location codes, bin hierarchies, and stock balances.

- Run trial imports before go-live.

6. Testing & User Acceptance (UAT)

Why it matters: Skipping thorough testing is the #1 reason WMS projects fail at go-live.

Testing checklist:

- Functional tests: receiving, putaway, picking, packing, dispatch, returns.

- Stress tests: simulate peak-season loads.

- Edge cases: partial shipments, stockouts, mis-scans.

- Integration tests: end-to-end data flow with ERP/TMS.

- UAT: involve real warehouse staff to ensure usability.

7. Training & Change Management

Why it matters: Even the best WMS fails without user adoption.

Training best practices:

- Role-specific training (operators, supervisors, IT support).

- Hands-on sessions with real devices.

- Easy-to-follow SOPs and quick reference guides.

- Change management communication: explain why the WMS is being implemented, not just how.

Pro tip: Use “super users”—early adopters who can support peers post go-live.

8. Go-Live & Ramp-Up

Options

Big bang: Entire warehouse switches at once (high risk, faster transition).

Phased rollout: Start with one area (receiving, picking) and expand (lower risk, longer timeline).

Best practices

- Choose a low-volume season.

- Keep legacy system running in parallel for backup.

- Have vendor and project team on-site for rapid troubleshooting.

9. Continuous Improvement

Why it matters: WMS isn’t a one-time setup—it should evolve with your business.

Post-go-live steps:

- Monitor KPIs vs baseline.

- Collect staff feedback and fine-tune workflows.

- Review system patches and upgrades regularly.

- Explore advanced features: labour management, slotting optimisation, predictive analytics.

You May Also Like to Read: Warehouse Slotting and Its Importance

Common Pitfalls to Avoid in WMS Implementation

1. Rushing the Process – Unrealistic deadlines skip proper testing and training. A phased rollout with checkpoints ensures smoother adoption.

2. Dirty Data Migration – Inaccurate SKUs or locations cause inventory chaos. Clean and standardise data before importing into the WMS.

3. Over-Customisation – Excessive tweaks make upgrades expensive and complex. Stick to standard features unless a process truly requires customisation.

4. Ignoring Infrastructure – Weak Wi-Fi or outdated scanners slow operations. Assess and upgrade your warehouse tech backbone in advance.

5. Underestimating Training Needs – Poorly trained staff resist the system, leading to errors. Provide role-based training and ongoing support.

6. Weak Integration Strategy – Manual workarounds creep back if ERP, TMS, or e-commerce platforms aren’t well integrated. Plan for seamless data flows early.

Best Practices for WMS Success

1. Engage End-Users Early – Involve warehouse operators and supervisors during design and testing. Their feedback ensures workflows are practical and encourages smoother adoption.

2. Document Workflows and Exceptions – A clear record of processes, exceptions, and training materials reduces confusion and helps maintain consistency across shifts and new hires.

3. Start with Incremental Pilots – Instead of a risky big-bang launch, test the WMS in a single warehouse or process area. Use insights from the pilot to fine-tune before scaling.

4. Track ROI with Clear Metrics – Monitor KPIs like order cycle time, dock-to-stock speed, picking accuracy, and labour utilisation. Continuous tracking demonstrates value and highlights areas for optimisation.

5. Plan an Upgrade Roadmap – WMS should evolve with your business. Keep an upgrade plan aligned with future needs like robotics, voice picking, or IoT-driven automation.

Conclusion

Implementing a Warehouse Management System is not just about software—it’s about transforming your warehouse into a data-driven, scalable, and resilient operation. Success comes from structured planning, accurate data, robust testing, and above all, people adoption. When done right, WMS delivers rapid ROI and positions your business for sustainable growth.

Action Point: Begin with a comprehensive needs assessment. This one step lays the foundation for a smooth, value-driven WMS journey.

Thank You For Reading: How to Implement a Warehouse Management System (WMS)?: Step By Step Guide

Powered By: 360Presence