What Is Safety Stock? Importance in Demand and Inventory Risk

Table of Contents

What Is Safety Stock?

Safety stock is the additional inventory held at a warehouse or fulfillment center to protect outbound operations from uncertainty.

It ensures that picking, packing, and dispatch continue uninterrupted when:

- Actual order volumes exceed forecasts

- Inbound shipments arrive late

- Transport lead times fluctuate

- Supplier deliveries fail or arrive incomplete

Safety stock exists purely to protect delivery commitments and warehouse flow, not to hedge financial forecasts.

Importance of Safety Stock in Logistics

In real-world logistics, variability is constant. Trucks don’t arrive exactly on time. Orders don’t arrive in neat patterns. Promotions distort volumes. Weather, congestion, and capacity constraints disrupt schedules.

Without safety stock:

- Dispatch docks sit idle despite demand

- Pickers waste time chasing unavailable SKUs

- Emergency freight increases operating costs

- Customer delivery promises are broken

Safety stock acts as operational insurance, allowing logistics teams to absorb disruption without slowing fulfillment.

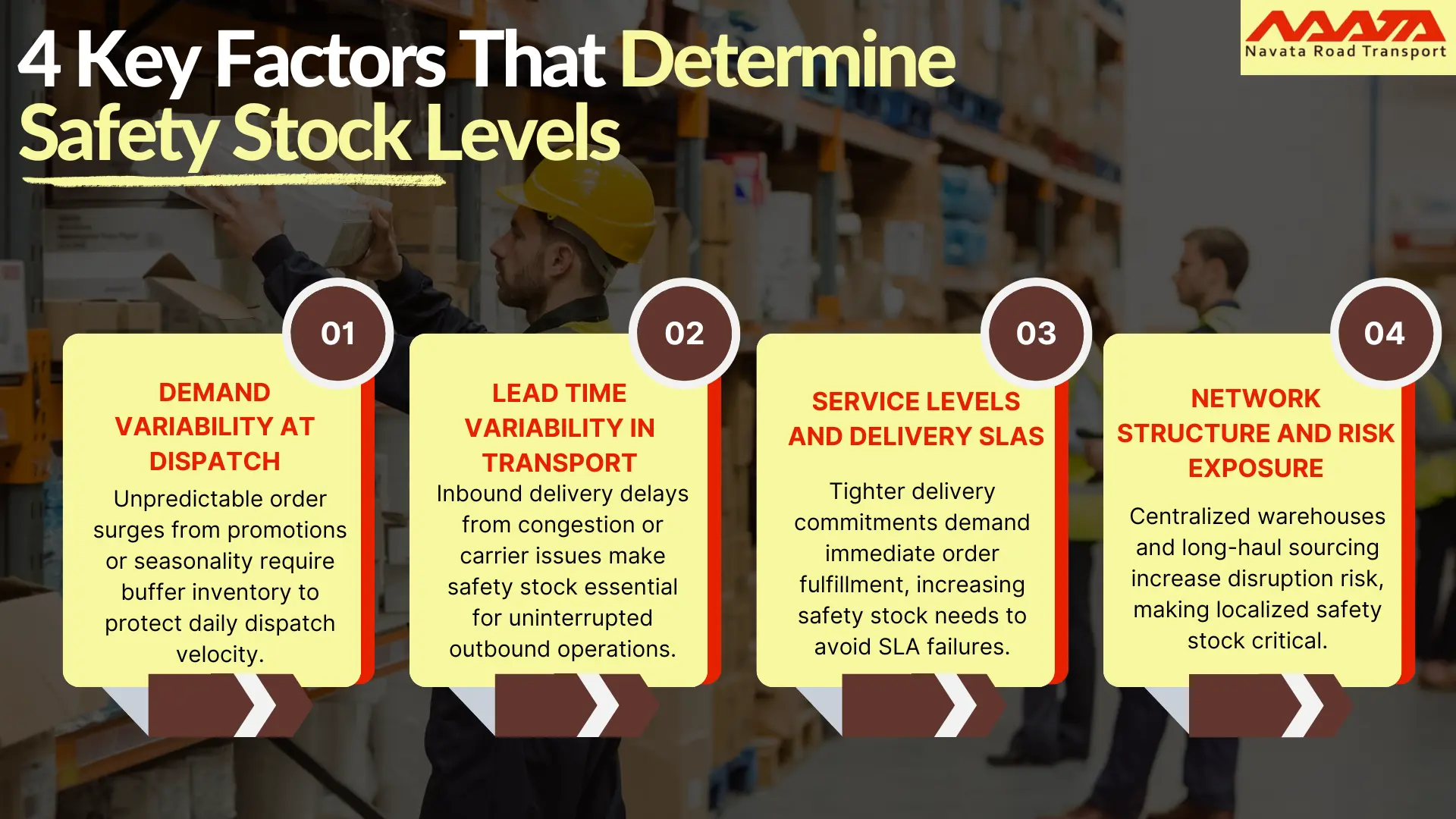

Key Logistics Factors That Determine Safety Stock Levels

Demand Variability at the Dispatch Level

From a logistics perspective, demand variability isn’t theoretical — it’s visible on the warehouse floor. Certain SKUs surge unpredictably due to promotions, regional buying behavior, marketplace sales, or seasonality. When outbound order volumes fluctuate sharply, warehouses need buffer inventory to maintain dispatch velocity.

High-volatility SKUs require higher safety stock near fulfillment zones to prevent pick delays, partial shipments, and missed cut-off times.

Lead Time Variability in Transportation

In logistics, lead time inconsistency is one of the biggest safety stock drivers. Inbound replenishment depends on carrier availability, route reliability, transit congestion, and external disruptions. When inbound trucks arrive later than planned, outbound operations still need to run.

Safety stock bridges the gap between planned inbound schedules and real-world transport delays, keeping dispatch operations stable even when upstream movement fails.

Service Level Commitments and Delivery SLAs

Logistics performance is measured by delivery promises — same-day, next-day, or time-window commitments. The tighter the SLA, the lower the tolerance for stockouts.

To maintain high on-time delivery performance, logistics teams must hold sufficient safety stock to fulfill orders immediately, without waiting for replenishment. As service expectations rise, safety stock requirements increase non-linearly.

Logistics Network Structure and Risk Exposure

Warehouses supported by:

- Single-source suppliers

- Long-haul inbound routes

- Cross-border or port-dependent transport

- Centralized fulfillment models

face higher disruption risk. When alternatives are limited, even minor delays cascade into delivery failures.

Safety stock provides localized resilience, allowing warehouses to operate independently of upstream volatility for short periods.

Cost of Stockouts vs Cost of Holding Inventory

In logistics, the real cost of a stockout is rarely just lost sales. It includes:

- Missed dispatch windows

- Penalty clauses and chargebacks

- Emergency freight costs

- Labor inefficiencies

- Customer churn and contract risk

For logistics management, the cost of not shipping is often far higher than the cost of holding planned buffer inventory. Safety stock reduces firefighting, not increases waste.

How Safety Stock Supports Daily Logistics Operations?

From a practical standpoint, safety stock:

- Keeps pick lines running during inbound delays

- Prevents partial truck loads caused by missing SKUs

- Reduces last-minute carrier rescheduling

- Stabilizes labor planning during demand spikes

- Improves dock utilization and dispatch reliability

Well-managed safety stock smooths warehouse flow, which directly improves transport efficiency and delivery predictability.

Where Safety Stock Should Be Held in Logistics Networks?

Effective logistics teams place safety stock strategically:

- Closer to high-volume delivery zones

- At fulfillment centers handling volatile SKUs

- At nodes with unreliable inbound transport

- At hubs supporting premium delivery SLAs

Blindly increasing inventory everywhere increases cost. Targeted safety stock placement improves resilience without bloating storage.

Role of Technology in Managing Safety Stock

Modern logistics operations rely on systems — not intuition — to manage safety stock.

Advanced WMS, OMS, and demand-planning tools:

- Track real-time outbound velocity

- Monitor inbound lead time variability

- Adjust safety stock dynamically by SKU and location

- Prevent overstock while protecting service levels

Technology transforms safety stock from a static buffer into a living operational control mechanism.

Safety Stock vs Overstock: The Critical Difference

Overstock happens when inventory grows without purpose.

Safety stock is deliberate, measured, and tied to logistics risk.

The difference lies in:

- Clear triggers for usage

- Defined replenishment rules

- SKU-level performance tracking

- Alignment with delivery commitments

When managed correctly, safety stock reduces total transportation cost — even though inventory levels appear higher.

Conclusion

In logistics, speed, reliability, and delivery accuracy define performance. Safety stock is what allows those metrics to remain stable when reality deviates from plan.

It protects warehouses from demand shocks, buffers transport delays, and ensures outbound operations continue without disruption. Far from being excess inventory, safety stock is a core logistics control lever — one that separates reactive operations from resilient, high-performing logistics networks.

For logistics leaders, the question is no longer whether to hold safety stock, but where, how much, and how intelligently it is managed.

Thank You For Reading: What Is Safety Stock? Importance in Demand and Inventory Risk

Powered By 360Presence