7 Best Supply Chain Technology Trends & Innovations

Table of Contents

Supply Chain Technology Trends

The competitiveness of companies in the logistics market is aided by efficient supply networks. Supply chain management, according to one research, provides businesses an advantage over rivals and allows them to grow their company. As a result of advances in data analytics and automation, the supply chain has never been more efficient.

Companies, employees, and consumers all benefit from new technologies that spur innovation in supply chains across various sectors. Technologies with a high potential for transformation are now trending, and they seek to increase operations’ resilience and resistance since we live in a digitally linked world.

Even while the future is always unpredictable, it is probably more so today than ever before. A worldwide pandemic has damaged the supply-chain sector at the same time that it has reemphasized its significance and that it has spawned completely new objectives and outlooks for the foreseeable future.

You May Also Like To Read : Supply Chain and Logistics Management are Not the Same

7 Best Supply Chain Technology Trends & Innovations

1. Internet of Things

Physical devices are linked to the Internet of Things (IoT), which monitors and transfers data without human involvement. The use of IoT in logistics increases inventory management efficiency by increasing visibility across the supply chain.

The Internet of Things (IoT) has transformed supply chain management (SCM). There are significant improvements in the ability to comprehend where products are located, how they are kept, and when they may be anticipated at a particular place.

Sensors can anticipate equipment wear and tear, enabling replacement parts to be ordered in advance. The Internet of Things (IoT) improves supply chain visibility.

It seems as if the Internet of Things (IoT) is reaching maturity. According to data, the number of companies using Internet of Things devices has increased from 11 percent in 2013 to 28 percent in 2020.

The International Data Corporation (IDC) predicts yearly growth of 13.6 percent until 2022. Organizations can monitor inventory, automate stock reordering, and keep track of deliveries all in real time thanks to the Internet of Things.

It’s easy to see why IoT is so attractive, given how it can be used across the whole supply chain. Its outcomes enable businesses to improve productivity, reduce downtime, anticipate consumer needs, and boost total return on investment (ROI).

2. Artificial Intelligence

Since the preceding decade, automation has been a trend in almost every industry. The fact that they’ve been so successful over the last year shows that this is a trend that will continue. Particularly noteworthy is the rise of artificial intelligence (AI) as a major force behind supply-chain automation.

Artificial intelligence algorithms coupled with machine learning enable businesses to be proactive in responding to demand changes. For instance, managers may use AI-based forecasting tools to plan supply chain operations and identify cost-cutting opportunities.

Real-time reporting, interactive data visualisation, and enhanced intelligence are all provided by these technologies, which are all found in business applications.

As more companies have access to Big Data, AI and machine learning are becoming more popular as a means of streamlining operations and automating procedures. According to Gartner, the number of companies using artificial intelligence has increased by 270 percent in the four years leading up to 2019.

Algorithms based on predictive analytics and machine learning are being used to enhance planning and decision support systems, detect buying trends, and automate time-consuming warehousing operations.

You May Also Like To Read : Discussing What is Supply chain management and It’s Objectives/Functions/Components

3. Augmented Data Intelligence

Managing supply chains requires continuous decision-making, and most companies lack the knowledge they need to do so.

As a result, businesses need solutions that help them get a better understanding of their supply chain and the activities that take place inside it, so that choices can be made using current and accurate data. The integration of multiple technologies is known as enhanced data intelligence (EDI). With each other, they speed up sophisticated data processing and provide useful insights, forecasts, and recommendations.

Data intelligence that has been enhanced may be used in conjunction with current business applications. This kind of solution has the capacity to gather data, examine correlations between it, and analyse it in order to give supply chain executives with the knowledge they need to make better business choices.

4. Warehouse Automation

Automation of inventory movement into, within, and out of warehouses to consumers with little human intervention is known as warehouse automation. By automating repetitive physical tasks and manual data input and analysis as part of a business’ operations, the company saves time and money.

Humans are still involved in warehouse automation systems that span everything from unloading trucks to completing orders. In this article, we’ll examine several kinds of warehouse automation, how they operate, and the main advantages that warehouses get from adopting automation technology.

It’s natural for employees to be concerned that warehouse robots or automated systems would take their jobs. However, by implementing these technologies, the lives and employment of everyone who works in warehousing and manufacturing will be improved — from labourers and foremen to the business owner. Automated technologies that perform demanding, repetitive jobs allow up employees to concentrate on more value-added activities improve worker safety and morale.

Warehouse automation has many advantages. One of the first advantages warehouse managers notice when they begin automating their operations is a decrease in the number of human mistakes. If the cost of a mistake is $60, you’re looking at a substantial effect on your company’s earnings. However, studies indicate that errors cost between $60 and $350.

5. Robotics

By incorporating robots into logistics, supply chain operations will be faster and more accurate, and human error will be reduced. Robots outperform human employees in terms of uptime and productivity. Unlike humans, robots do not replace them; instead, they work in tandem with people to improve productivity.

Automation of robotic processes helps supply chain managers find and improve inefficiencies across the network. Using artificial intelligence, RPA makes it possible for managers to operate a seamless operation round-the-clock.

SCM automation encompasses not just activities but also manual chores. In North America alone, robotic automation received $850 million in investments in the first two quarters of 2018. Drones are increasingly being utilised for the delivery of lightweight items in transportation. Although self-driving cars aren’t here now, they may be in the near future.

Automation is becoming more popular as businesses try to meet the competing needs of omnichannel supply chains and, in particular, the requirement for flexibility and agility. Warehouse activities like sorting, counting, and even getting and transporting items are perfect for robots.

Some of the world’s largest supply chain companies are also putting money into self-driving cars to save on labour expenses, eliminate the possibility of human harm on the road, and improve fuel economy. Every one of these factors contributes to a higher Return on Investment (ROI).

You May Also Like To Read : Is Logistics and Supply Chain Interrelated ?

6. Last-Mile Delivery

After the warehouse or distribution centre, a large percentage of a company’s overall transportation costs are incurred by the consumer. The most critical aspect of logistics is last-mile delivery since it has a direct impact on customer satisfaction. Yet there are a number of issues with last-mile delivery, including delays brought on by traffic and the idiosyncrasies of customers as well as regulations and delivery density.

For companies, this is the most important stage in the delivery process and the one where speed and efficiency are most important considerations In the e-commerce, food, and retail sectors in particular, customers’ need for fast delivery is always rising. As a result, it is the most costly part of the trip.

Modern delivery software can show companies where their trucks are in real time, whether they’re deviating from their intended path, and how much time they’ve been sitting idle. This not only provides logistics and supply chain managers more control over their fleet, but it also reduces theft and spoiling to a minimum. Predictive visibility is also an option, where the technology informs the shipper of where the cargo should be at a certain moment.

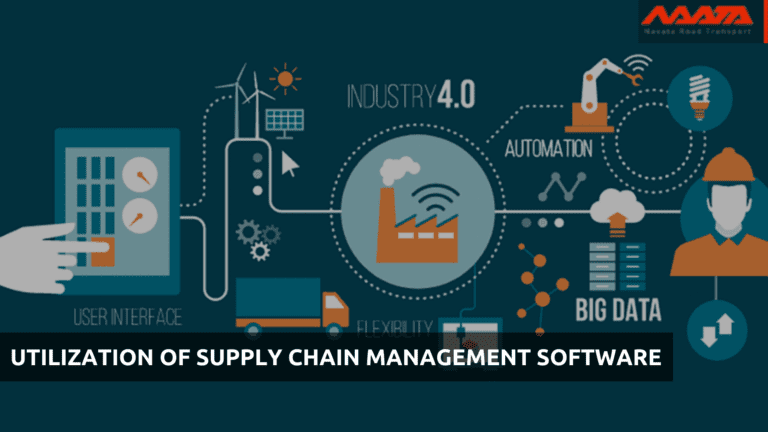

7. Utilization of Supply Chain Management Software

Logistics software, such as TMS (Transport Management Software), is very beneficial to supply chain management firms. For supply chain managers, TMS provides a digital platform that helps them improve fleet operations by monitoring inventories and supplies in real time across the supply chain.

Fleet management used to be a labor-intensive manual process with a high probability of mistake. Warehousing and inventory management are both automated using logistics software. As a result, accuracy increases, operational expenses are reduced, and there is more openness between companies and the general public.

Thanks For Reading : 7 Best Supply Chain Technology Trends & Innovations

Powered By 360Presence

Supply Chain Technology Trends & Innovations Supply Chain Technology Trends & Innovations Supply Chain Technology Trends & Innovations