Top 8 Benefits of Warehouse Automation for Modern Businesses

Table of Contents

Benefits of Warehouse Automation for Modern Businesses

In today’s competitive business world, speed, accuracy, and efficiency can make or break your success—especially when it comes to warehouse operations. That’s where warehouse automation steps in. It replaces time-consuming manual tasks with smart technologies like robots, sensors, and warehouse management systems (WMS).

Whether you’re running an e-commerce store, a distribution center, or a retail supply chain, understanding the benefits of warehouse automation can give your business a powerful edge. Let’s explore the key advantages in simple terms.

Read More About: 7 Types of Warehousing and Concept of Warehousing

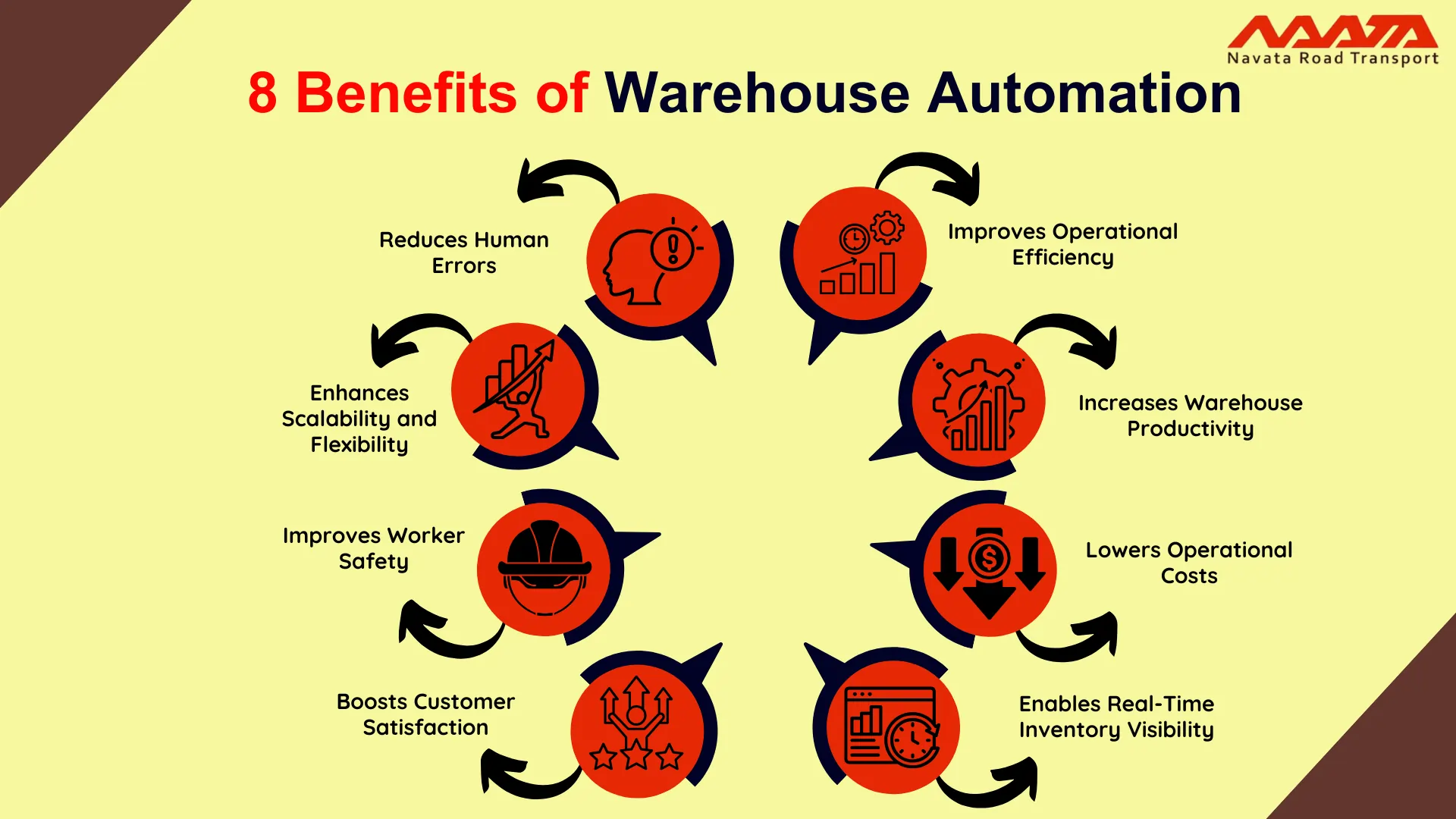

1. Reduces Human Errors

Manual processes, no matter how skilled your team is, are prone to mistakes—like shipping the wrong item or mislabeling packages. These errors not only hurt your bottom line but also affect customer trust.

One of the biggest benefits of warehouse automation is its ability to significantly reduce human errors. With technologies like barcode scanners, RFID, and pick-to-light systems, automation ensures accurate order picking, labeling, and inventory tracking. This leads to faster delivery, fewer returns, and happier customers.

2. Improves Operational Efficiency

Machines don’t need breaks easily, don’t get tired, and work around the clock. By automating key warehouse tasks like picking, packing, sorting, and shelving, your team can get more done in less time—with better results.

This is one of the standout benefits of warehouse automation—it dramatically improves your operational efficiency. Processes that once took hours can now be completed in minutes, making your warehouse run smoother and faster than ever.

3. Increases Warehouse Productivity

Imagine if your team had more time to focus on high-value work instead of walking around the warehouse looking for items. That’s exactly what automation offers.

With tools like automated guided vehicles (AGVs), autonomous mobile robots (AMRs), and conveyor systems, tasks get done faster and more accurately. These systems handle the repetitive jobs, while your staff focuses on quality control, customer support, or process improvement.

As a result, overall warehouse productivity rises—sometimes by as much as 35%, especially during peak sales seasons.

4. Lowers Operational Costs

One concern businesses have about automation is cost. Yes, there’s an upfront investment, but the long-term savings are worth it. Warehouse automation reduces your need for excessive labor, cuts down on overtime, and minimizes costly errors. It also saves money on returns, damages, and inefficient use of space.

Over time, these savings add up, making automation a cost-effective solution with a solid return on investment (ROI). Leading companies like Amazon and IKEA have seen remarkable cost reductions through smart warehouse automation.

5. Enables Real-Time Inventory Visibility

Knowing exactly what’s in your warehouse at any moment is crucial—but nearly impossible with manual systems. One of the key benefits of warehouse automation is real-time inventory visibility.

With connected sensors and automated tracking, you can monitor every item from arrival to shipment. You’ll know what’s in stock, what’s low, and what’s on the move—all in real time. This helps you make better decisions, avoid overstocking or running out of products, and respond quickly to changes in demand.

You May Also Like to Read: 14 Easy Inventory Management Techniques

6. Boosts Customer Satisfaction

Customers expect fast, accurate, and reliable service. If you deliver the wrong product or ship it late, they’re unlikely to order again. Automated warehouses are designed to deliver the right product at the right time, every time. This level of consistency improves the customer experience and builds trust.

Fewer errors and faster deliveries mean fewer complaints, returns, and bad reviews—leading to higher customer retention.

In a world where customer loyalty is everything, this is one of the most valuable benefits of warehouse automation.

7. Improves Worker Safety

Traditional warehouses can be risky. Workers often lift heavy items, operate machinery, and move through crowded spaces—all of which increase the chances of accidents.

Automation helps reduce these risks by handling the heavy lifting and minimizing human contact with dangerous equipment. Robots and machines can safely perform tasks that would be risky for humans, such as reaching high shelves or moving bulky items.

The result? Fewer workplace injuries, a safer environment, and a more satisfied workforce.

8. Enhances Scalability and Flexibility

As your business grows or seasonal demand spikes, you need systems that can scale quickly. Hiring and training temporary workers every time demand increases is time-consuming and expensive.

Automation solves this. With scalable warehouse automation solutions, you can increase output without expanding your workforce. Systems can be scaled up to handle more orders or adjusted to focus on new products—without skipping a beat.

This flexibility keeps your operations agile, responsive, and future-ready.

You May Also Like to Read: How Technology Is Impacting & Transforming Warehouse Management

Conclusion

The benefits of warehouse automation are clear—reduced errors, increased productivity, real-time visibility, and improved safety, just to name a few. Whether you’re a growing e-commerce startup or an established logistics giant, automating your warehouse can transform the way you operate.

In a world where customer expectations are rising and competition is fierce, automation is no longer optional—it’s essential.

Are you ready to unlock the full potential of your warehouse?

Thankyou For Reading: Top 8 Benefits of Warehouse Automation for Modern Businesses

Powered By 360Presence

Leave a Replay

warehouse automation management systems warehouse automation management systems warehouse automation management systems