6 Components of Supply Chain

Table of Contents

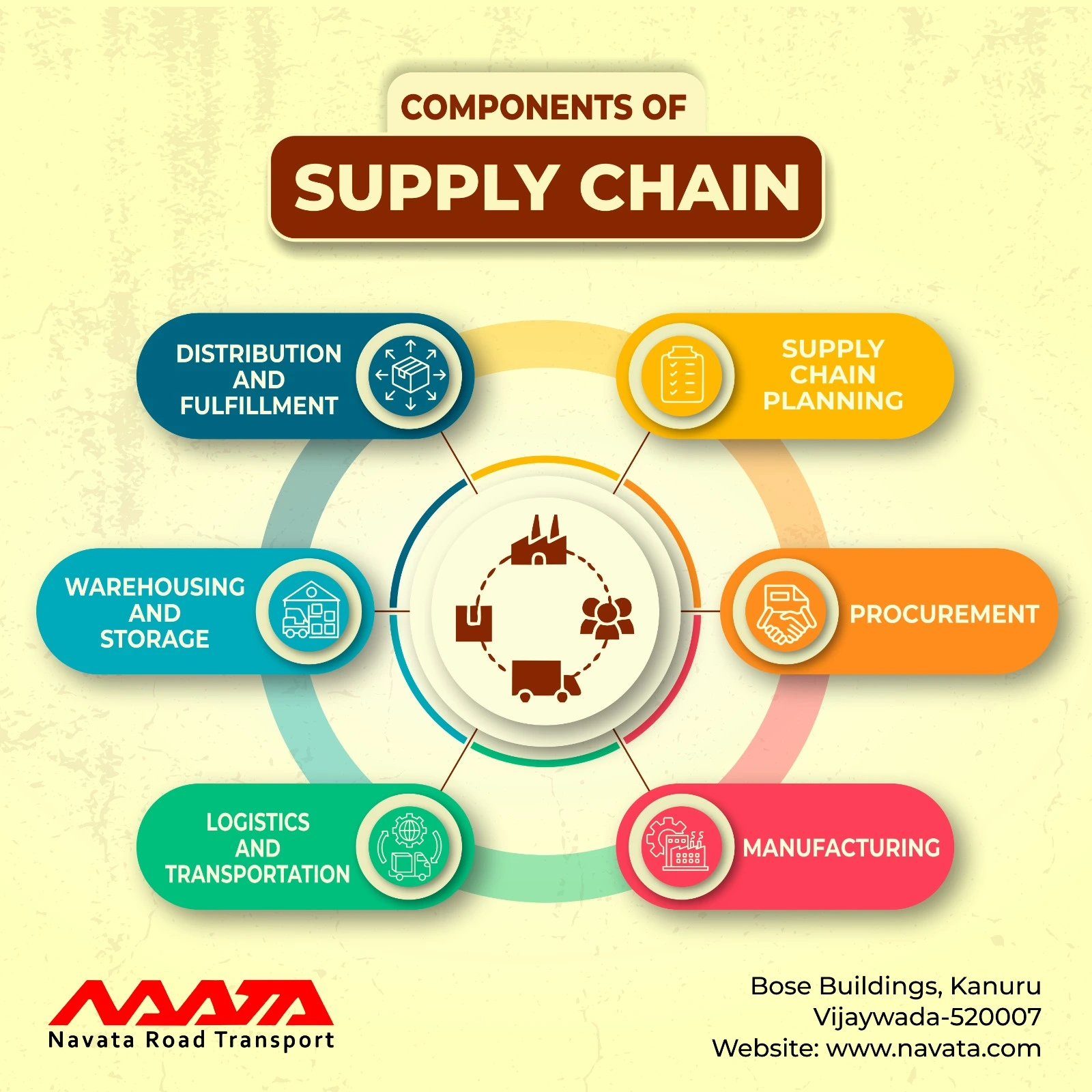

6 Components of Supply Chain

In the intricate world of business operations, the supply chain stands as a backbone, orchestrating a symphony of processes that ensure products move seamlessly from conception to the hands of the end consumer. This intricate dance involves various components, each playing a crucial role in maintaining the rhythm of the supply chain.

In this blog, we will delve into the key components of the supply chain, exploring the nuances of:

- Supply chain planning,

- Procurement,

- Manufacturing,

- Logistics and Transportation,

- Warehouse and Storage,

- Distribution and Fulfillment.

Supply Chain Planning

Supply chain planning is the foundational element of the entire supply chain process, acting as the strategic conductor that orchestrates the movement of goods from the initial concept to the hands of the end consumer. This critical component involves a comprehensive and forward-looking approach to ensure that the supply chain operates efficiently, responsively, and in line with organizational goals. Let’s delve deeper into the key aspects of supply chain planning:

Demand Forecasting

At the core of supply chain planning is accurately predicting future demand. Demand forecasting involves analyzing historical data, market trends, and other relevant factors to estimate the quantity of products or services that will be needed. Accurate forecasting minimizes the risk of overstock or stockouts, allowing organizations to optimize inventory levels and production schedules.

Production Planning

Once demand is forecasted, the next step is to align production schedules accordingly. Production planning involves determining what, when, and how much to produce. It considers available resources, production capacity, and lead times. Efficient production planning ensures that the manufacturing process is synchronized with demand, preventing inefficiencies and disruptions in the supply chain.

Supplier Collaboration

Supply chain planning extends beyond the boundaries of an organization. Collaborating with suppliers is essential to synchronize the entire supply chain network. This collaboration involves sharing information about demand forecasts, production schedules, and inventory levels. Transparent communication with suppliers helps build strong partnerships, reduce lead times, and enhance overall supply chain resilience.

Risk Management

In an ever-changing global landscape, supply chain planning must account for various risks, including geopolitical issues, natural disasters, and market fluctuations. Developing risk mitigation strategies and contingency plans ensures the supply chain can adapt to unforeseen challenges. This proactive approach minimizes disruptions and helps maintain a steady flow of goods.

Procurement

Procurement, often called the art and science of obtaining goods and services, is a pivotal component within the supply chain. It involves the systematic process of identifying, selecting, and acquiring the necessary inputs from raw materials to finished goods from external sources. Just as a composer carefully selects instruments for a symphony, procurement professionals strategically choose suppliers and negotiate contracts to ensure the highest quality at the best possible cost. In this segment, we’ll explore the key aspects of procurement and its critical role in the overall efficiency and success of the supply chain.

Strategic Supplier Selection

At the core of effective procurement lies the strategic selection of suppliers. This process involves evaluating potential suppliers based on various criteria such as quality, reliability, cost, and geographical location. Procurement professionals conduct thorough assessments to identify partners who align with the company’s values and objectives. The goal is not just to find a source of materials but to establish a long-term, mutually beneficial relationship that contributes to the overall resilience of the supply chain.

Contract Negotiation and Management

Once suppliers are identified, the next step is to negotiate contracts that outline the terms and conditions of the partnership. This includes pricing, payment terms, delivery schedules, and quality standards. Contract management is an ongoing process, ensuring that both parties fulfill their obligations and that adjustments can be made to accommodate market conditions or changes in business needs. Transparent and well-defined contracts set the tempo for a smooth and harmonious procurement process.

Supplier Relationship Management (SRM)

Cultivating strong relationships with suppliers is a nicety and a necessity in modern procurement. Supplier Relationship Management (SRM) involves ongoing communication, collaboration, and performance monitoring. A robust SRM strategy goes beyond transactional interactions, fostering innovation and continuous improvement. This collaborative approach ensures that suppliers are not just vendors but strategic partners invested in the success of the entire supply chain.

Ethical and Sustainable Procurement

Procurement extends beyond financial considerations in an era where corporate social responsibility is gaining prominence. Ethical and sustainable procurement practices ensure suppliers adhere to ethical labor practices, environmental standards, and social responsibility. Companies increasingly recognize the importance of aligning procurement practices with broader corporate values, contributing to a more sustainable and socially responsible global supply chain.

Manufacturing

The third component of the supply chain, manufacturing, is a pivotal stage in the journey of a product from raw materials to finished goods. This phase involves the transformation of inputs into tangible products, embodying the creative and technical aspects of bringing a concept to life. Manufacturing serves as the creative epicenter where the raw materials and components are carefully crafted and assembled to produce the final product. Let’s explore the intricacies of the manufacturing component in the supply chain.

Design and Engineering

The manufacturing process often begins with design and engineering. This phase involves creating detailed plans and specifications for the product. Design considerations include functionality, aesthetics, and manufacturability. Advanced technologies like Computer-Aided Design (CAD) and simulation tools enable engineers to optimize designs before physical production begins, reducing the risk of errors and improving efficiency.

Raw Material Procurement

Procuring high-quality raw materials is a critical aspect of manufacturing. Just as a musician selects the finest instruments, manufacturers must ensure that the materials used meet stringent quality standards. Efficient procurement processes, often integrated with the broader supply chain, are essential for maintaining a stable and cost-effective supply of raw materials.

Production Processes

The heart of manufacturing lies in production processes. This is where the raw materials are transformed through various stages into the final product. Depending on the industry and product complexity, manufacturing processes can range from traditional methods to highly automated and technologically advanced procedures. Techniques such as Lean Manufacturing and Six Sigma aim to optimize production processes, eliminating waste and ensuring efficiency.

Quality Control

Quality control is the vigilant monitoring and testing of products at various stages of the manufacturing process. Ensuring that each product meets or exceeds quality standards is akin to tuning each note in a melody to perfection. Robust quality control measures not only prevent defective products from reaching consumers but also contribute to overall process improvement.

Automation and Industry 4.0

The advent of automation and Industry 4.0 technologies has transformed the manufacturing landscape. Robotics, the Internet of Things (IoT), artificial intelligence, and big data analytics are seamlessly integrated into production processes. This not only enhances efficiency and precision but also enables manufacturers to adapt quickly to changing demands and market conditions.

Supply Chain Integration

Manufacturing doesn’t operate in isolation; it is deeply interconnected with other supply chain components. Tight integration with supply chain planning, procurement, and logistics ensures that production aligns with demand forecasts, raw materials are readily available, and finished goods seamlessly move through the supply chain. Collaboration with suppliers and customers is vital for maintaining a responsive and agile manufacturing ecosystem.

Logistics and Transportation

Logistics and transportation are pivotal components in the supply chain that focus on the physical movement of goods from their origin to their final destination. This segment is like the supply chain’s arteries and veins, ensuring products’ efficient flow across various touchpoints.

Logistics Management

Logistics management involves coordinating and optimizing all activities related to the movement of goods. This encompasses a range of tasks, such as order fulfillment, inventory management, packaging, and warehousing. The objective is to streamline processes to enhance overall efficiency and reduce costs. Advanced technologies like warehouse management systems (WMS) and enterprise resource planning (ERP) systems are crucial in optimizing logistics operations.

Route Optimization

In logistics and transportation, route optimization is a critical aspect. It involves determining the most efficient path for goods to travel from the point of origin to the destination. This optimization considers transportation costs, fuel efficiency, and delivery time. With the help of advanced software and algorithms, businesses can identify the most cost-effective and time-efficient routes, minimizing delays and maximizing resource utilization.

Visibility and Tracking

Visibility and tracking technologies provide real-time insights into the location and status of shipments. This is crucial for supply chain stakeholders who need to monitor the movement of goods to ensure timely deliveries. RFID (Radio-Frequency Identification) and GPS (Global Positioning System) technologies have revolutionized tracking, offering precise information that enhances transparency and allows quick decision-making.

Last-Mile Delivery

In recent years, last-mile delivery has gained immense importance, especially with the rise of e-commerce. The last mile refers to the final leg of the delivery process, where goods are transported from a distribution center to the end consumer. Efficient last-mile delivery is essential for meeting customer expectations regarding speed, accuracy, and flexibility. Companies are exploring innovative solutions such as autonomous vehicles, drones, and local distribution centers to optimize last-mile logistics.

Warehouse and Storage

In the symphony of the supply chain, the Warehouse and Storage component acts as the backstage, the place where the crescendo is held before the grand performance. This crucial element is more than just a physical space to store goods; it’s a dynamic hub that plays a pivotal role in maintaining optimal inventory levels, facilitating order fulfillment, and ensuring the seamless flow of products from manufacturing to distribution. Let’s explore the intricacies of Warehouse and Storage within the supply chain.

Inventory Management

Effective inventory management is the conductor’s baton that orchestrates the movement of goods within the warehouse. It involves keeping track of stock levels, monitoring product demand, and strategically placing items to optimize space and accessibility. Advanced inventory management systems, often integrated with warehouse management systems (WMS), empower businesses to maintain real-time visibility into their stock, minimizing the risk of stockouts or overstock situations.

Value-Added Services

Warehouses are not only storage facilities but also centers for value-added services that enhance the overall customer experience. These services may include kitting, labeling, packaging customization, or product assembly. By offering these additional services, warehouses contribute to the uniqueness and customization of the final product, creating a melody that resonates with customer preferences.

Space Optimization

Space optimization is the choreography of the storage dance within a warehouse. It involves strategically placing products to make the most efficient use of available space. This may include utilizing vertical space with mezzanine levels or implementing high-density storage solutions like pallet racking systems. The goal is to maximize storage capacity while maintaining accessibility for efficient picking and packing operations.

Technology Integration

The modern Warehouse and Storage component is characterized by the integration of cutting-edge technologies. Warehouse Management Systems (WMS), Internet of Things (IoT) sensors, and RFID (Radio-Frequency Identification) tags contribute to real-time tracking and monitoring of inventory. Automated storage and retrieval systems (AS/RS) and robotics enhance efficiency, reduce manual errors, and accelerate order processing. The technological ensemble ensures that warehouses operate with precision and adaptability, contributing to the overall agility of the supply chain.

Safety and Compliance

Ensuring the safety of both personnel and stored goods is a paramount concern within the Warehouse and Storage component. Compliance with regulations related to storage conditions, product handling, and employee safety is crucial. Implementing safety protocols, conducting regular inspections, and investing in training programs contribute to creating a secure environment, safeguarding the integrity of the entire supply chain.

You Might Also Like To Read: 5 Roles of Warehousing in Logistics and Supply Chain

Distribution and Fulfillment

The Distribution and Fulfillment stage is the grand finale of the supply chain symphony, where products reach their ultimate destination – the hands of the end consumer. This critical component involves a series of intricate processes aimed at ensuring that goods are delivered accurately, efficiently, and in a timely manner.

Order Processing

The journey of distribution and fulfillment often begins with order processing. This involves receiving and validating customer orders, managing order details, and preparing them for fulfillment. Modern technologies such as order management systems and electronic data interchange (EDI) have streamlined this process, reducing errors and expediting the transition from order placement to fulfillment.

Warehousing in Distribution

Distribution centers act as pivotal hubs in the supply chain, facilitating the storage, sorting, and packing of products before they embark on their final journey. These centers are strategically located to optimize transportation routes and reduce lead times. Warehouse technologies, including robotics, automated picking systems, and advanced warehouse management systems, enhance efficiency and accuracy in order fulfillment.

Transportation

Transportation is the lifeline of distribution and fulfillment, connecting various points in the supply chain and ensuring products move seamlessly from warehouses to retailers or directly to customers. The choice of transportation modes, whether by truck, rail, air, or sea, depends on factors such as speed, cost, and the nature of the products being transported. Innovations in transportation, such as track-and-trace technologies and real-time visibility solutions, enable businesses to monitor and optimize the movement of goods.

Last-Mile Delivery

In the age of e-commerce, last-mile delivery has gained prominence as the final and often most challenging leg of the distribution journey. The “last mile” refers to the distance from the distribution center to the customer’s doorstep. Meeting customer expectations for fast and reliable deliveries has become a competitive differentiator. Companies are experimenting with various last-mile solutions, including autonomous vehicles, drones, and collaborative delivery models, to enhance the speed and efficiency of final product delivery.

Order Fulfillment Technologies

To enhance the speed and accuracy of order fulfillment, businesses are increasingly turning to automation technologies. Automated order picking systems, conveyor belts, and sorting systems play a crucial role in expediting the movement of products through distribution centers. Robotics and artificial intelligence are also making significant contributions to order fulfillment, improving efficiency and reducing the reliance on manual labor.

Conclusion

In conclusion, the supply chain is a harmonious collaboration of various components, each playing a unique role in creating a seamless operation. From the initial planning stages to the final delivery of products, every step requires precision, coordination, and adaptability. Embracing technological advancements and adopting best practices in each component ensures that the supply chain remains resilient in the face of evolving market dynamics. As businesses continue to navigate the complexities of global markets, a well-orchestrated supply chain becomes not only a competitive advantage but a fundamental requirement for sustained success.

Thanks For Reading: 6 Components of Supply Chain

Powered By 360Presence